2023.08.01.8

Files > Volume 8 > Vol 8 No 1 2023

Indicator framework for large-scale cacao (Theobroma cacao L.) in vitro plant production planning and controlling

Ana María Henao Ramírez 1,* , David Hernando Palacio Hajduk 2

, David Hernando Palacio Hajduk 2 , Diana Maria Cano Martínez 3

, Diana Maria Cano Martínez 3 , Aura Inés Urrea Trujillo 4

, Aura Inés Urrea Trujillo 4

1 Center of Agrobiotechnological Development and Innovation – CEDAIT, Universidad de Antioquia, Km. 1.7 vía San Antonio de Pereira - Carmen de Viboral, A.A 054048, Colombia; [email protected].

2 Center of Agrobiotechnological Development and Innovation – CEDAIT, Universidad de Antioquia, Km. 1.7 vía San Antonio de Pereira - Carmen de Viboral, A.A 054048, Colombia; [email protected].

3 Center of Agrobiotechnological Development and Innovation – CEDAIT, Universidad de Antioquia, Km. 1.7 vía San Antonio de Pereira - Carmen de Viboral, A.A 054048, Colombia; [email protected].

4 Biology Institute, Universidad de Antioquia, Calle 70 No. 52-21, Medellín, A. A 050010, Colombia; [email protected].

* Correspondence: [email protected]; Tel.: +57 3013920674

Available from: http://dx.doi.org/10.21931/RB/2023.08.01.8

ABSTRACT

Somatic embryogenesis (SE) is considered the most suitable and integrated biotechnology for the large-scale production of clonal cacao plants compared to conventional methods. Hence, the scale-up of relevant technologies must be interfaced with effective and efficient management of productive processes at an industrial scale like biofactories. Production facilities like biofactories serve to transform plant resources into products like plantlets. This technology constitutes an essential innovative variant since it allows obtaining high multiplication coefficients in short periods. Currently, there is no reference to carrying out adequate planning of the entire production process; for this reason, it is not used for the maximum production capacity of the facilities, and there is a high level of uncertainty. With the aid of production planning and controlling (PPC) systems, inputs can be planned to achieve a determined output of products. Therefore, this work proposes a production planning and controlling (PPC) system for SE cacao plantlet multiplication through the pilot large-scale. This paper presents input and output information considering the leading indicators of the production process, like materials, labor, quality, and performance. Emphasis is placed on technical details on the production process of 100.000 plantlets in batches from the CCN51 genotype. Through the model analysis, challenges and requirements for PPC system have been defined as a basis for future works and will have successfully managed the production process.

Keywords: Commercial-scale propagation, cost of production, indicators, somatic embryo, vegetative propagation.

INTRODUCTION

The production program's central nervous system, production planning and control (PPC) oversee making sure that all materials and components of the assembly are available at the appropriate times, locations, and in the proper quantities to allow operations to proceed following the predetermined schedules while incurring the least amount of costs 1 . However, in the construction of the production system is essential to understand the production system. PPC collaborates with procurement, manufacturing, and program management to create strategies to meet client needs. Production planning is dynamic by nature and always remains in flux since plans may need to be modified in response to situation 2 .

Input-output models are usually used to simplify natural systems 3 . The models can be used to answer a research question and explore how the system behaves in particular circumstances 4 . There are no broad principles for creating an input-output system 5 . Günther and Velten (2014)4 outlined the four general phases that must be followed to describe and analyze the behavior of a system:

(1) System analysis;

(2) Modeling;

(3) Simulation;

(4) Validation.

System analysis's first step involves gathering all the data needed to explain the system's behavior under consideration. In step two, a model is created, for example, analytically, numerically, or probabilistically based on the data that was gathered in step one. The model describes the relationship between the system's input and output information. The model is converted into a simulation in step three. The initial experiments are conducted to display the simple design based on the data gathered in step one. The simulation results are validated in step four to address the research issues in a natural system.

In step one of system analysis is essential the selection of indicators. An indicator monitors an issue or condition and demonstrates a desired outcome. Hands are varied and depend on the type of systems they watch, with different levels of complexity 6 . A system's status 3zcan be described via indicators. Choosing the appropriate indicators requires a scientific and technical understanding of how the system functions and what data are needed 7 .

An indicator does not mean the same as an indication or goal; an arrow is generally quantifiable by aggregating different and multiple data. The resulting information is synthesized and used to measure goal achievement. Indicators should be based on criteria and present some characteristics, such as specific, measurable, understandable, relevant, realistic, reliable, etc. 8 .

In the Input-output model for conventional PPC systems, production facilities transform raw materials into products, typically producing a predetermined output in quantity and quality at the lowest possible cost 9 . For this transformation process, PPC systems serve two primary purposes. First, with the help of PPC systems, labor, costs, and raw material input are planned to produce specific items. Second, PPC systems manage orders through product delivery. The data bill of materials (BOM) and manufacturing plans are required for both functions 10 . A BOM is a formal list of raw materials that specifies the components needed to make a particular product. Work plans outline the procedures that must be taken to generate a specific product. The description includes details on the requirements for workstations, the interval between two subsequent processes, the production times, which are broken down into waiting time, setup time, processing time, and clearing time, as well as the raw materials that must be used 11 .

In plant production through ES, we must solve the research question aimed at identifying the anticipated real cost of production in the biofactory facilities. The first step is to develop a system analysis, which uses the input and output model and describes the behavior of the system's production from a PCC perspective in a biofactory. A search for biofactory indicators is carried out, where an overview of relevant indicators for choosing appropriate indicators for PPC processes in plant biotechnology is not presented. To fill this gap, this paper presents information for current PPC systems in plant production by SE. An input-output model has been created, and PPC systems have been defined as a platform for further research and study through the analysis of plant biotechnology requirements and challenges.

MATERIALS AND METHODS

In the analysis system, each part of the ES cacao plant production at the biofactory was detailed. The required input and output information to describe the behavior of the considered procedure was collected with the direction of staff belonging to the biofactory of Universidad de Antioquia and researchers with significant experience in ES cacao production 12–17 . Production plans and data bill of materials (BOM) for 100.000 batch plant production were realized according to Gronau, (2014) 10 (Supplemental 1 and 2). From BOM and production plan following Joung et al. (2013) 8 conceptual proposals have selected the indicators based on the following criteria and characteristics:

(1) Specific: An indicator should be detailed and transparent as possible, precisely formulated to measure only the desired output;

(2) Measurable: Clearly and concretely, the indicator defines the measurement type, allowing data collection to be consistent and comparable. It can be easily measured by quantitative or qualitative means;

(3) Understandable: An indicator should be easily interpreted, and one should know exactly what the output of an indicator demonstrates to act accordingly to the needs;

(4) Relevant and realistic: An indicator must be appropriate, fitting the measuring purpose and underlying the pointed issue, directly related to meaningful and purposeful aspects, and realistic considering that the needed data to calculate the indicators should be collected only through available resources, not being the collection too tricky or too expensive.

(5) Reliable: It must give an accurate picture of what is measured, which does not mean the same as being precise, but instead that it contains trusted and accurate information.

(6) Timely manner: The data collection, calculation, and evaluation must be done promptly, providing a structure that allows meaningful progress monitoring. In other words, it should be perfectly stated the desired frequency for calculating the indicator to track the outcome results better;

(7) Long-term-oriented: It must ensure their future use and reflect the development and adoption of organizational, process or product changes.

RESULTS AND DISCUSSION

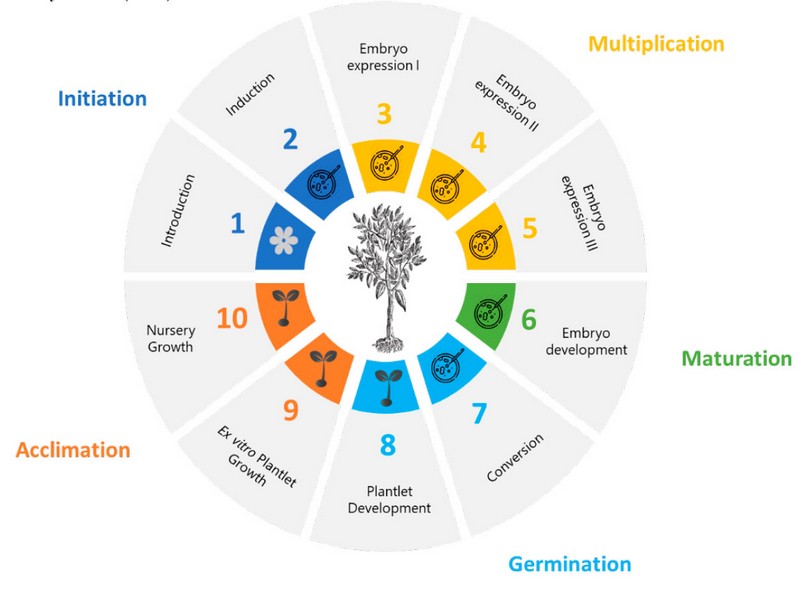

It is the result of more than ten years of research, development of knowledge and experience in the production of elite plants from biotechnological techniques to improve the agro-industrial output similar to other biotechnologies in South America 18 . Different production stages were identified in the analysis system of the SE cacao plant production. SE as a productive approach is a complex process involving other biological mechanisms in each one of its stages: initiation, multiplication, maturation, and germination, as reported by Egertsdotter et al. (2019) 19 . The initiation stage includes the introduction to in vitro conditions (laboratory) and the induction phase. In the introduction phase, the plant material from the donor or parental plants is taken from field conditions to the laboratory for a disinfection process and obtaining sterile material. In the induction phase, the plant material in controlled conditions is required a culture medium that promotes cellular differentiation and the formation of embryogenic cells 20 . Once the embryogenic potential is induced, indirectly pro, embryonic masses (PEM) are formed 21 . At this point, the SE allows unlimited multiplication of the original plant material 22 . Cacao SE could be developed directly on previously somatic embryos in a process called secondary or recurrent somatic embryogenesis producing more embryos in multiplication stage 15 . The change of culture conditions in embryogenic tissues allows the somatic embryo development through the maturation and germination stages23–25 . In the conversion phase, the embryo transitions to a plantlet with the extension of the first leaves, elongating the stem and forming primary and secondary roots. Then, the plantlets continue developing until they form at least -14 leaves, a stem, and roots with a length greater than 3-10 cm. Subsequently, the obtained plantlets can be transferred to ex vitro conditions for hardening or acclimatization. The seedlings adapt to the new environmental needs in the greenhouse with a specific substrate, lighting, and adequate irrigation. Later, seedlings are transferred to a new substrate, and when they reach sufficient growth, they are taken to the nursery for their subsequent transfer to the field (Figure 3-1.). The productive approach is like another successful process of plant in vitro propagation like Al-Aizari et al. (2020) 2 ; Dhiman et al. (2021) 2 ; Sriskanda et al. (2021) 2 ; Vyas et al. (2021) 2 .

Figure 1. Flow chart of the plantlets production stages via somatic embryogenesis for different cacao genotypes.

Different informational elements on controls are considered for the productive process of cacao plantlets. This allows measuring the degree of objective attainment desired to be achieved in each stage of the process. The following has been taken into account when creating indicators in each stage: (1) Plant production requires a close relationship between the stages of SE and labor operations; (2) Labour operations must be executed in an inviolable sequential manner from the initiation stage to acclimation (3) The type of tissue obtained at the end of a phase of the initial material for the subsequent phase; (4) Labour operations are entirely manual and are the basis for calculating the work (amount of plant material by the vessel being processed by workday per person).

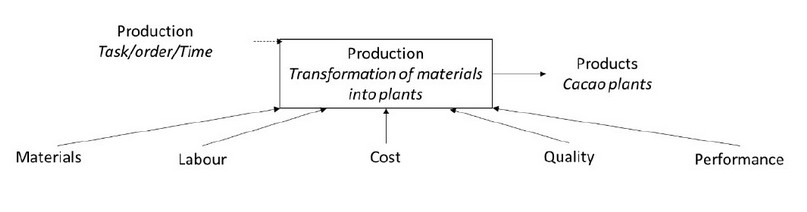

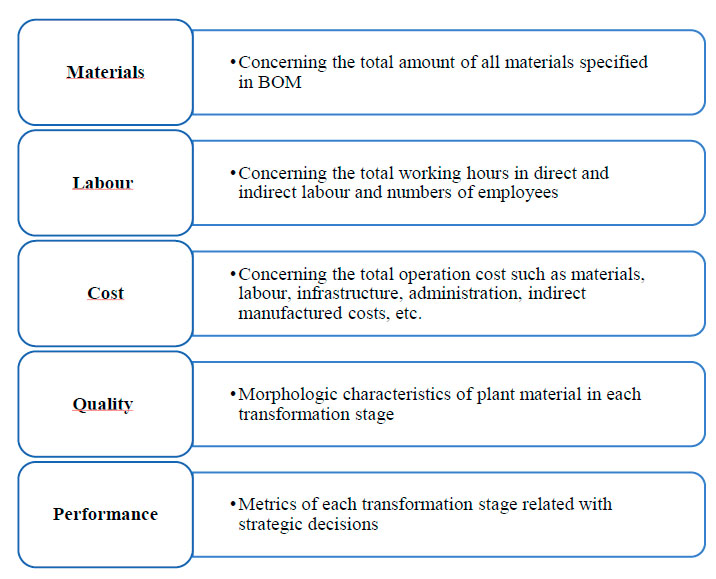

Based on BOM (Supplemental 1) and production plan description (Supplemental 2) for each stage: initiation, development, maturation, germination, and acclimation of ES cacao plant production and the needed requirements to create useful input-output model, figure 3-2 shows an overview of a basic model for PPC systems. The indicators for PPC systems for ES plant production were categorized into five groups: materials, costs, labor, quality, and performance (Figure 3-3), similar to Chen, (2016) 30 .

Figure 2 Input-output model for somatic embryogenesis (SE) cacao plant production planning and controlling (PPC) system.

Materials

The total materials used to produce and package the plantlets are detailed in BOM (Supplemental 1). This includes raw materials and items required for manufacturing but is not part of the finished product. The group of indicators materials considers the predictable material consumption from production, in particular, the materials needed to prepare culture media and the consumables used in the process operation such as chemical products, gelling agents, culture vessels, glassware, culture tools, laboratory tools and other various items that are necessary for the process 31 .

Figure 3. The indicator categorization structure contains five main groups: materials, costs, labor, quality, and performance for ES plant PPC system.

Labour

The group of labour indicators considers the production facility's workers' predictable work schedules. The total number of workers in production determines how many people are employed. For Colombia, a potential working time per month of 166 hours was obtained (Supplemental 2). Labour was defined in two ways, direct and indirect labor, indirect labour there are considered functions in the laminar flow chamber in all production stages like disinfection of explants, disinfection of tools and containers, bowl protection removal, vessels opening, cutting of the explants, culture medium replacement, selection of keys with embryos, cut to separate the embryos, selection by the size of embryos, material discard, closing of the reseeded container, container labeling, fill tracking lists, etc. In indirect labor, some people perform operational and technical functions and work individually in the purchase of reagents, preparation of transport boxes for plant material from the field, repackaging reagents, storage, weighing of reagents, preparation of culture medium, autoclaving of culture media and materials, dispensing of culture media, washing of glassware and tools, etc.

Following Cervelli and Senaratna (1995) 32 supervisory positions must also be considered, including those in charge of supervising direct work. For example, a supervisor must calculate the number of vessels and culture media required daily and weekly and manage chemical products, media stock, equipment, and the maintenance of the respective laboratory stations for working. They ensure all explants start producing on schedule, in the correct quantities, and without contamination. Besides, they are responsible for maintaining productivity and, most importantly, managing the group of direct workers and deciding whether crop production must be continued, harvested, or discarded at their discretion.

The strategy implemented to monitor the work carried out by an operator is using productivity norms or standards (W), which are obtained from the average time it takes for the personnel to carry out a particular activity. The staff is expected to develop a volume of processes at each time. The following table presents an abstract of the action and the unit of measure (Supplemental 2).

Cost

The group of indicators costs reflects the actual and anticipated expenses of production. The total economic value is the sum of material of culture medium materials, direct and indirect labor of employees including wages, benefits, indirect cost of manufacturing like transportation and laboratory tools and operation expenses. Operation expenses are cash payments for facilities, energy, services purchased, depreciation of construction, installations, and equipment (refrigerator, oven, autoclave, scale, pH meter, magnetic stirrer, stereomicroscope, water distillation unit, lighted shelves, timers, air conditioning, orbital shakers, etc.) and administration 33 . Payments for the services received include those to independent contractors, staffing firms, and other service providers (e.g., maintaining a machine). Employee salary, employee taxes, levies, unemployment funds, and total benefits, including pensions, insurance, health, and safety, make up the entire payroll 34 .

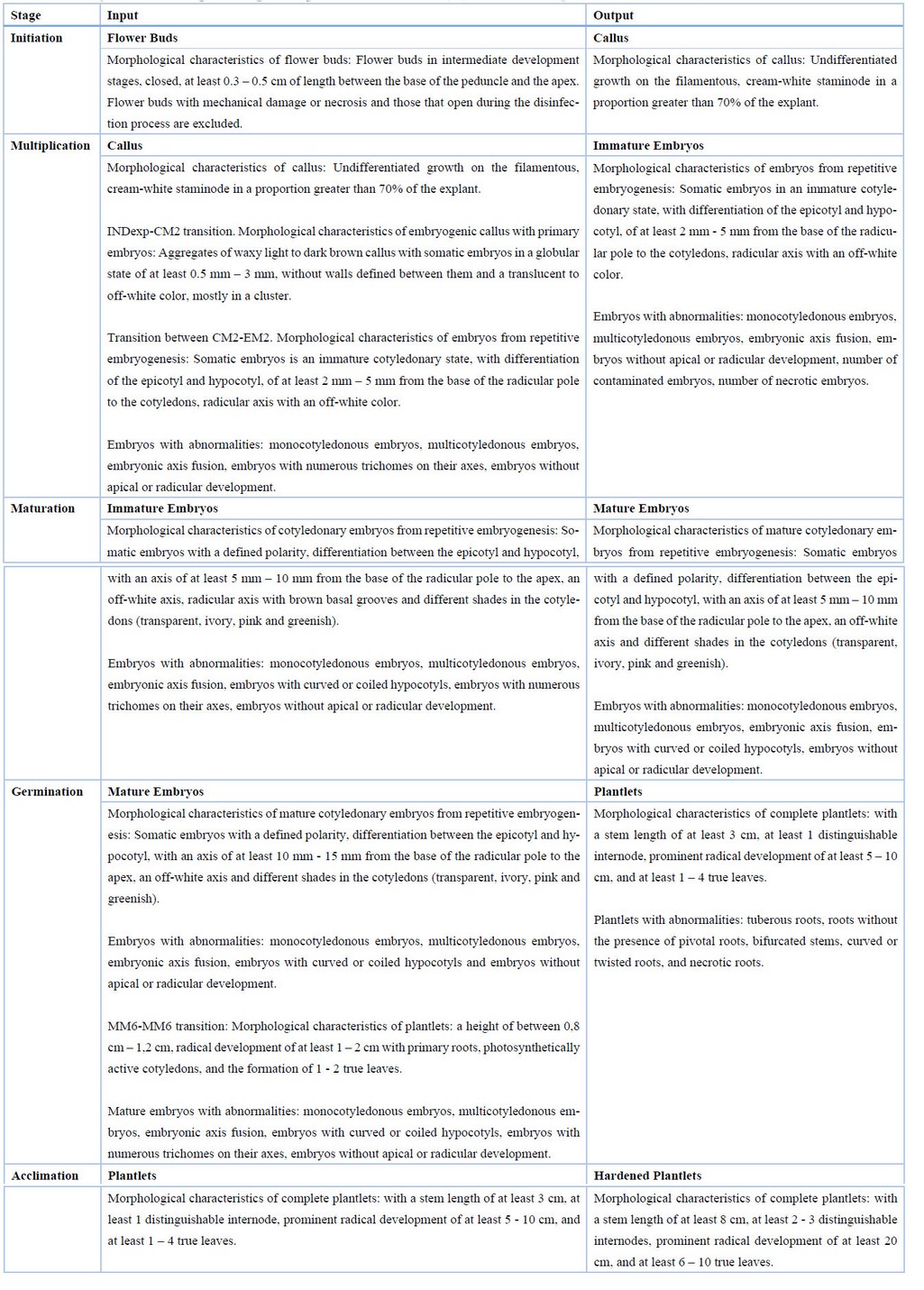

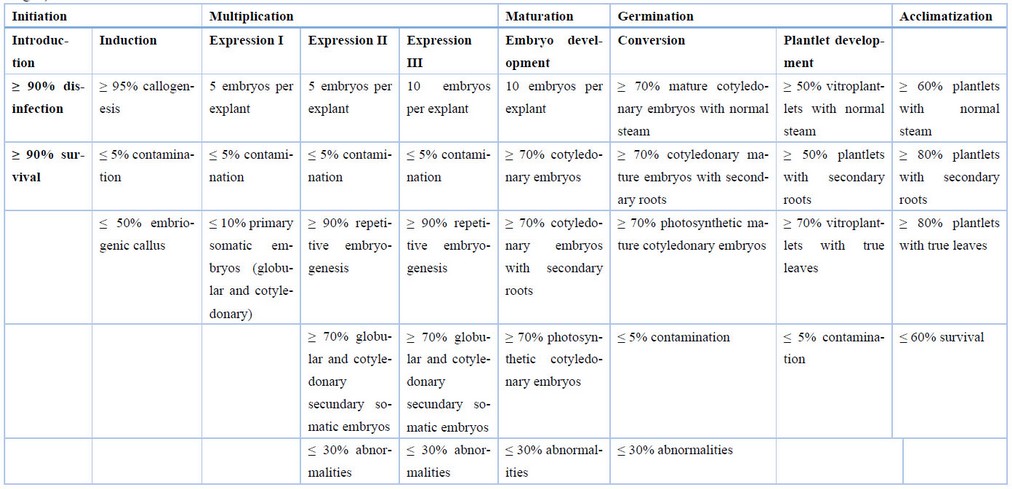

Quality

Quality indicators are tangible and quantifiable measurement instruments that evaluate the quality of each process's stages, considering both input and output factors. The ideal morphological characteristics of flower buds, primary embryogenic callus, globular embryos, repetitive somatic embryos and plantlets are specified for each stage. In addition, indicators such as microbial contamination, necrosis and abnormality are also specified (Table 3-1).

Table 1. Quality indicators for producing cacao plantlets in a biofactory (initiation, multiplication, maturation, germination, and acclimation stages).

Performance

Performance indicators allow qualitatively and quantitatively demonstrating progress in each stage expressed as percentages defined following the productive biofactory-scale works 35,36 and practical experience (Table 3-2). Three leading indicators were defined: disinfection, biological response and multiplication coefficients.

Percentages of disinfection: The production process requires a high level of safety, which can be jeopardized by involving contaminated material, contamination of the culture medium, or contamination caused by poor washing of containers. Contamination processes are too risky since they can lead to the complete loss of a production batch.

Percentage of biological response: It is estimated that only a portion of the plant material introduced in the process generates a callus, which develops embryos, and these develop into seedlings without malformations. According to quality indicators (Table 3-1).

Multiplication coefficients: In the multiplication stages of the production process, there are three phases in which several embryos are obtained from one callus and previous sources. This process is strategic since it exponentially increases the formation of embryos that become seedlings.

For each stage defined, percentages of disinfection, survival, microbial contamination, callogenesis, callus-forming embryos, primary globular somatic embryos, primary cotyledonary somatic embryos, callus with recurrent embryogenesis, different types and amounts of existing abnormalities, cotyledonary embryos with secondary roots, photosynthetically active cotyledonary embryos, typically developed in vitro plantlets, normally produced ex vitro plantlets, etc. (Table 3-2).

Table 2. Performance indicators for producing cacao plantlets in a biofactory (initiation, multiplication, maturation, germination, and acclimatization stages).

Figure 3-2 also shows the information stream production Task/Order/Time and the indications. It is feasible to normalize the indicators using this information. The input indicators for "Expenses" and "Materials" can be expressed as time, production tasks, material consumption, or costs per production order 37 . The normalized indicator can be used to improve production efficiency by, among other things, benchmarking procedures, comparing equal production orders, and monitoring production 38 . The set of product indicators also reflects the output of the production process. The outcome of products generated in production using input materials is the weight or volume of such products.

In this sense, the Task/Order/Time refers to the efficiency of the production process; it is the flower ratio that enters the process concerning the seedlings that leave it. In the efficiency of the production process, it is sought to reduce the number of explants such as cacao flowers that enter the production process and that the number of plants that leave it is more significant.

CONCLUSIONS

PPC plays an essential role in modern production enterprises. Current production management systems consider resources such as material, labor and production capacity and their respective costs but sometimes neglect the quality and performance for cost savings. The PPC system has been identified, and analytical modeling of the operation of the productive propagation was carried out through ES plant cacao production, in which the primary and support activities were identified, with the respective consumption, until the final product was obtained. With the data from the model, the simulation was carried out, in which the indicators considered of greater relevance are monitored, which tells us about the production process. This work constitutes the first step toward approximating costs closer to reality.

Supplementary Materials: The following are available online at www.revistabionatura.com/xxx/s1, Table Supplemental 1: Data bill of materials, Sheet 1 Inventory Sheet. Supplemental 2 Production Plan Sheet 1 Batch Plants to be obtained, Sheet 2 Stages of production, Sheet 3 Direct and indirect labor, Sheet 4 Culture medium and tools, Sheet 5 Assumptions.

Author Contributions: Conceptualization, Ana María Henao Ramírez and Aura Inés Urrea Trujillo; methodology Hernando David Palacio Hajduck and Diana Maria Cano Martinez; validation and formal analysis, Ana María Henao Ramírez and Diana Maria Cano Martinez; investigation, resources, data curation, writing—original draft preparation, Ana María Henao Ramírez; writing—review and editing and supervision, Aura Inés Urrea Trujillo. All authors have read and agreed to the published version of the manuscript.

Funding: This research was funded by the General Royalties System - Science, Technology, and Innovation Fund with the Center of Agrobiotechnological Development and Innovation– CEDAIT- BPIN 2016000100060, National Planning Department, Office of the Governor of Antioquia, Universidad de Antioquia, Universidad Católica de Oriente and Compañía Nacional de Chocolates.

Acknowledgments: We would like to thank the Laboratory of Plant Physiology and Plant Tissue Culture of the Universidad de Antioquia. A special acknowledgment to Universidad de Antioquia xand Granja Yariguíes – Compañia Nacional de Chocolates.

Conflicts of Interest: The authors declare no conflict of interest.

REFERENCES

1. Akmal A, Podgorodnichenko N, Greatbanks R, Everett AM. Bibliometric analysis of production planning and control (1990–2016). Production Planning & Control. 2018;29(4):333-351.

2. Belhadi A, Touriki FE, El Fezazi S. Benefits of adopting lean production on green performance of SMEs: a case study. Production Planning & Control. 2018;29(11):873-894.

3. Bonney M. Reflections on production planning and control (PPC). Gestao & Producao. 2000;7(3):181-207.

4. Günther M, Velten K. Mathematische Modellbildung Und Simulation: Eine Einführung Für Wissenschaftler, Ingenieure Und Ökonomen. Wiley-VCH GmbH; 2014. https://books.google.com.co/books?id=ekyCoAEACAAJ

5. Moreau V, Massard G. Material and Energy Flow Analysis. Published online 2017. doi:10.1093/acrefore/9780199389414.013.109

6. Schreiber M, Schutte CSL, Braunreuther S, Reinhart G. A performance measurement system for integrated production and maintenance planning. Procedia CIRP. 2020;93:1037-1042. doi:https://doi.org/10.1016/j.procir.2020.03.041

7. Bila M. Developing an Input-Output Model for Benchmarking Company Resource Usage. Universidade Nova de Lisboa; 2016.

8. Joung CB, Carrell J, Sarkar P, Feng SC. Categorization of indicators for sustainable manufacturing. Ecol Indic. 2013;24:148-157. doi:10.1016/j.ecolind.2012.05.030

9. Stark R, Seliger G, Bonvoisin J. Sustainable Manufacturing: Challenges, Solutions and Implementation Perspectives. Springer Nature; 2017.

10. Gronau N. Enterprise resource planning. Architektur, Funktionen und Management von ERP-Systemen. 2014;2.

11. Trost M, Claus T, Herrmann F. Master Production Scheduling and the relevance of included social criteria. ACC Journal. Published online 2017.

12. Gallego A, Henao A, Urrea A, Atehortúa L. Polyphenols distribution and reserve substances analysis in cocoa somatic embryogenesis. Acta Biolo Colomb. 2016;21(2):335-345. doi:http://dx.doi.org/10.15446/abc.v21n2.50196

13. Henao A, Salazar H, Urrea A. Quality of cocoa (Theobroma cacao L.) DNA from foliar tissue at different stages of development. Acta Agron. 2018;67(2):1-10. doi:10.15446/acag.v67n2.63046

14. Henao A, De-La-Hoz T, Ospina T, Garcés L, Urrea A. Evaluation of the potential of regeneration of different Colombian and commercial genotypes of cocoa (Theobroma cacao L.) via somatic embryogenesis. Sci Hortic. 2018;229:148–156. doi:10.1016/j.scienta.2017.10.040

15. Henao-Ramírez A, Urrea-Trujillo A. Somatic Embryogenesis for Clonal Propagation and Associated Molecular Studies in Cacao (Theobroma cacao L.). In: Chong P, Newman D, eds. Agricultural, Forestry and Bioindustry Biotechnology and Biodiscovery. Springer, Cham; 2020:63-102. doi:https://doi.org/10.1007/978-3-030-51358-0_5

16. Henao A, Jaime H, Duque S, Calle A, Urrea A. Determination of Genetic Stability in Cacao Plants (Theobroma Cacao L.) Derived from Somatic Embryogenesis Using Microsatellite Molecular Markers (SSR). International Journal of Fruit Science. 2021;00(00):1-15. doi:10.1080/15538362.2021.1873219

17. Osorio T, Henao A, de la Hoz T, Urrea A. Propagation of IMC67 Plants, Universal Cacao (Theobroma Cacao L.) Rootstock via Somatic Embryogenesis. International Journal of Fruit Science. 2022;22(1):78-94. doi:10.1080/15538362.2021.2023067

18. Galian CE, Cabral J, Jacobo LA, Suárez M. Industrial biotechnological laboratory with adjustable scale of the model of biofabricas-Phytolab. Brazilian Journal of Development. 2019;5(6):4513-4524.

19. Egertsdotter U, Ahmad I, Clapham D. Automation and scale up of somatic embryogenesis for commercial plant production, with emphasis on conifers. Front Plant Sci. 2019;10(February):1-13. doi:10.3389/fpls.2019.00109

20. Kouassi MK, Kahia J, Kouame CN, Tahi MG, Koffi EK. Comparing the effect of plant growth regulators on callus and somatic embryogenesis induction in four elite Theobroma cacao L. genotypes. HortScience. 2017;52(1):142-145. doi:10.21273/HORTSCI11092-16

21. Daouda K, Kan K, Alla N, Kouablan K. Induction of somatic embryos of recalcitrant genotypes of Theobroma cacao L. J Appl Biosci. 2019;133(1):13552. doi:10.4314/jab.v133i1.7

22. Fehér A. Callus, dedifferentiation, totipotency, somatic embryogenesis: What these terms mean in the era of molecular plant biology? Front Plant Sci. 2019;10(April):1-11. doi:10.3389/fpls.2019.00536

23. Garcia C, Marelli J, Motamayor J, Villela C. Somatic Embryogenesis in Theobroma cacao L. In: Loyola-Vargas V, Ochoa-Alejo N, eds. Plant Cell Culture Protocols, Methods in Molecular Biology. Vol 1815. Springer Science; 2018:227-245. doi:https://doi.org/10.1007/978-1-4939-8594-4_15

24. Ajijah N, Hartati R, Rubiyo R, Sukma D, Sudarsono D. Effective cacao somatic embryo regeneration on kinetin supplemented DKW medium and somaclonal variation assessment using SSRs markers. Agrivita. 2016;38(1):80-92. doi:10.17503/agrivita.v38i1.619

25. Bustami M, Werbrouck S. Somatic Embryogenesis in Elite Indonesian cacao Theobroma cacao L. In: Jain SM, Gupta P, eds. Step Wise Protocols for Somatic Embryogenesis of Important Woody Plants. Springer International Publishing AG; 2018:73-81. doi:10.1007/978-1-4939-8594-4_15

26. Sriskanda D, Liew YX, Khor SP, Merican F, Subramaniam S, Chew BL. An efficient micropropagation protocol for Ficus carica cv. Golden Orphan suitable for mass propagation. Biocatal Agric Biotechnol. 2021;38:102225. doi:https://doi.org/10.1016/j.bcab.2021.102225

27. Vyas KD, Ranawat B, Singh A. Development of high frequency cost-effective micropropagation protocol for Juncus rigidus using liquid culture medium and extraction of cellulose from their in vitro shoots - An important rush. Biocatal Agric Biotechnol. 2021;35:102099. doi:https://doi.org/10.1016/j.bcab.2021.102099

28. Al-Aizari AA, Al-Obeed RS, Mohamed MAH. Improving micropropagation of some grape cultivars via boron, calcium and phosphate. Electronic Journal of Biotechnology. 2020;48:95-100. doi:https://doi.org/10.1016/j.ejbt.2020.10.001

29. Dhiman N, Devi K, Bhattacharya A. Development of low cost micropropagation protocol for Nardostachys jatamansi: A critically endangered medicinal herb of Himalayas. South African Journal of Botany. 2021;140:468-477. doi:https://doi.org/10.1016/j.sajb.2021.04.002

30. Chen C. Cost analysis of plant micropropagation of Phalaenopsis. Plant Cell Tissue Organ Cult. 2016;126(1):167-175. doi:10.1007/s11240-016-0987-4

31. Prakash S, Hoque M, Brinks T. Culture media and containers. In: Low Cost Options for Tissue Culture Technology in Developing Countries. FAO/IAEA Division of Nuclear Techniques in Food and Agriculture; 2004:29-40.

32. Cervelli R, Senaratna T. Economic aspects of somatic embryogenesis. In: Aitken J, Kozai T, Lila M, eds. Automation and Environmental Control in Plant Tissue Culture. Springer Science; 1995:29-64. doi:10.1007/978-94-015-8461-6_3

33. Tomar UK, Negi U, Sinha AK, Danatu PK. An overview of the economic factors influencing micropropagation. In: Parihar P, Parihar L, eds. Advances in Applied Biotechnology. Agrobios. ; 2010:1-12.

34. Henao A, Palacio D, Urrea A. Cost Analysis of Cacao (Theobroma cacao L.) Plant Propagation through the Somatic Embryogenesis Method. Bionatura. 2022;7(2):1-13. doi:10.21931/rb/2022.07.02.2

35. Alvarez N. Desarrollo de Ecuaciones Funcionales Para El Apoyo a La Toma de Decisiones En La Planificación de La Producción Masiva de Plantas in Vitro Por Embriogénesis Somática En El IBP. Universidad Central" Marta Abreu" de Las Villas; 2014.

36. Sánchez C. Alternativas Para El Control de Malezas En El Cultivo de Cacao (Theobroma Cacao) En El Cantón Montalvo. Universidad Técnica de Babahoyo - Ecuador; 2018.

37. Stevenson M, Hendry LC, Kingsman BG. A review of production planning and control: The applicability of key concepts to the make-to-order industry. Int J Prod Res. 2005;43(5):869-898. doi:10.1080/0020754042000298520

38. Pechmann A, Zarte M. Procedure for Generating a Basis for PPC Systems to Schedule the Production Considering Energy Demand and Available Renewable Energy. Procedia CIRP. 2017;64:393-398. doi:https://doi.org/10.1016/j.procir.2017.03.033

Received: 28 December 2022 / Accepted: 15 January 2022 / Published:15 February 2023

Citation: Henao Ramírez A M, Palacio Hajduk D H, Cano Martínez D M, Urrea Trujillo A I. Indicator framework for large-scale cacao (Theobroma cacao L.) in vitro plant production planning and controlling.Revis Bionatura 2023;8 (1) 8. http://dx.doi.org/10.21931/RB/2023.08.01.8