2023.08.03.30

Files > Volume 8 > Vol 8 No 3 2023

Endotoxin quality of ultrapure dialysis fluid for online hemodiafiltration in several hemodialysis centers

1Environment and Water Directorate, Ministry of Science and Technology, Baghdad, Iraq; [email protected].

*Corresponding author. [email protected], 009647903265918Available from:Revis Bionatura 2023;8 (3) 30. http://dx.doi.org/10.21931/RB/2023.08.03.30

ABSTRACT

Globally, the nephrology community is seeing a rise in the use of high-flux membranes and ultrapure water in hemodialysis (HD) machines. However, data on HD water quality could be more extensive in low- and middle-income countries. The Ministry of Health in Iraq issued a rule requiring a gradual modification in the HD water treatment system to adopt ultrapure water in all dialysis centers. The current study aimed to monitor the endotoxin of ultrapure dialysis fluid at several centers in Iraq and the clinical benefits of its use. This work evaluated the quality of ultrapure water used for dialysis in twenty-one dialysis centers within various Iraqi province hospitals. The samples were collected for 4 months from January to April 2022. Endotoxin tests in ultrapure dialysis fluid were measured by Gel Clot assay. Results showed an unacceptable difference in the ultrapure dialysis fluid's quality compared to the international standard (ANSI/AAMI/ISO-23500). Endotoxin levels in 33% of ultrapure dialysis fluid above 0.03 EU/ml, exceeding recommended international standards. The findings highlight the importance of assessing water quality in medical facilities to ensure patient safety and encourage sanitary monitoring of this procedure as a healthcare promoter.

Keywords: Ultrapure water; Hemodiafiltration; Dialysis fluid; Endotoxin; Public Health Reform.

INTRODUCTION

Convective dialysis approaches, such as hemodiafiltration (HDF), are becoming the dialysis modality of choice due to the potential clinical benefits. Large volumes of plasma water are filtered through the dialyzer during online HDF. 1 HDF provided the most effective method for removing small and medium-sized uremic toxins by combining diffusive and solute transport across a highly permeable dialysis membrane. 2 To maintain fluid balance, sterile replacement fluids are also pumped directly into the bloodstream. After water purification and ultrafiltration, the municipal water supply produces these substitution fluids online. 3

The term "ultrapure" dialysis fluid was developed in the early 1980s to create a more stringent standard for the microbiological purity of dialysis fluid and to replace sterile and non-pyrogenic fluid due to the discovery that bacterial metabolites from dialysis fluid could pass the dialyzer membrane and stimulate the immune system, 4contributing to the heightened inflammatory state seen in hemodialysis patients.5 Furthermore, co-morbidities, such as anemia, diabetes mellitus, hypertension, dyslipidemia and thyroid disorders. 6 The primary distinction between ultrapure and standard dialysis fluid is its microbiologic quality, which is characterized in terms of maximum acceptable levels of bacteria and endotoxins according to the ISO/ANSI/AAMI 23500. 7Substitution fluids are produced via ultrafiltration of ultrapure dialysis fluids with a filter that has a logarithmic reduction value for microorganisms, defined as log10 (inlet concentration)/LRV (outlet concentration). 8

Since endotoxins can cause pyrogenic responses, septicemia, and even mortality when they reach the patient's blood, 9 enhancing water purity is essential. The regulations concerning the HD water treatment system in Iraq and the agreement between each dialysis center and the Iraqi Ministry of Health have not been amended for a long decade. On the contrary, worldwide dialysis water purification guidelines have evolved and continuously been updated by the ISO/ANSI/AAMI. 7

Consequently, the Ministry of Iraqi Health updated the HD water treatment system recommendations and closely monitored the policy's implementation and regular water analysis. The regulation mandated the use of ultrapure water in all Iraqi dialysis centers. To prevent the harmful effects of endotoxins, reducing their presence in the dialysis water and equipment is essential. This may include regular testing and monitoring of the water, using high-quality water sources, water treatment systems and filters, and proper equipment maintenance. 10 This study intends to assess the use of ultrapure dialysis fluid (UPDF) in some Iraqi hemodialysis (HD) centers that routinely treat patients with online HDF compared with the current ISO/ANSI/AAMI 23500 guideline.

MATERIALS AND METHODS

Work strategy and sampling

In the present study, data sets of endotoxin were collected over four months (January to April 2023) from Iraqi provinces. Seventy water samples were examined from the inlet water of hemodialysis machines. Thus, the research covers twenty-one dialysis centers from nine Iraqi provinces dialysis centers. Dedicated individuals (dialysis technicians) were responsible for sampling in an aseptic condition. The ultrapure dialysis fluid sample volumes were 200 ml on average.

Only one laboratory in Iraq has the equipment required to conduct the endotoxin test, and the Ministry of Science and Technology operates that lab. It has a detection limit of up to 0.015 EU/ml and uses a gel clot LAL endotoxin assay kit.

Water treatment of hemodialysis

All Reverse osmosis RO units in those centers operate on the same principle by pumping pressured water across a semipermeable membrane and filtering it through a cross-flow membrane filtration system. TEK-IMAS provided these has been selling GAMBRO dialysis products in Iraq since 2005 and is the exclusive distributor. Here, a single stream of water is introduced to the membrane, where it can either pass through as pure permeate or be "rejected" by the membrane and flow to the drain. Each center's total production capacity ranges from 1.5 to 4.5 m3/d, depending on the daily operating hours, which vary from 18 to 24 h with water-recovery rates of up to 85%. During a typical 4-h dialysis session, a patient is exposed to 120 L of purified water at a flow rate of 500 ml/min. As a result, RO rejection falls below 90% for draining. Furthermore, concentrated solutions include acetate, a class of concentrated solutions for HD.

Endotoxin test

Limulus amoebocyte lysate (LAL) testing by a gel clot assay, also known as bacterial endotoxin testing, was used to quantify endotoxin in ultrapure dialysis fluid collected samples into sterile glass bottles. LAL testing is an in vitro assay used to detect the presence and concentration of endotoxin in medical water. The sensitivity of the measuring kit is 0.015 and 0.06 EU/ml. 11

The sample is added to the appropriate reaction tube, along with 0.1 ml of dissolved LAL reagent, and the reaction is incubated in a water bath at 37 ±1 °C for 60 ±2 minutes without vibration as part of the evaluation process. After the incubation period has ended, tilt the tube through 180º gradually but quickly. The outcome is positive if a gel forms and keeps its integrity without deforming or collapsing; the result is negative if no gel forms.

Analytical statistics

To analyze the data, Microsoft Excel 2010 was used.

RESULTS

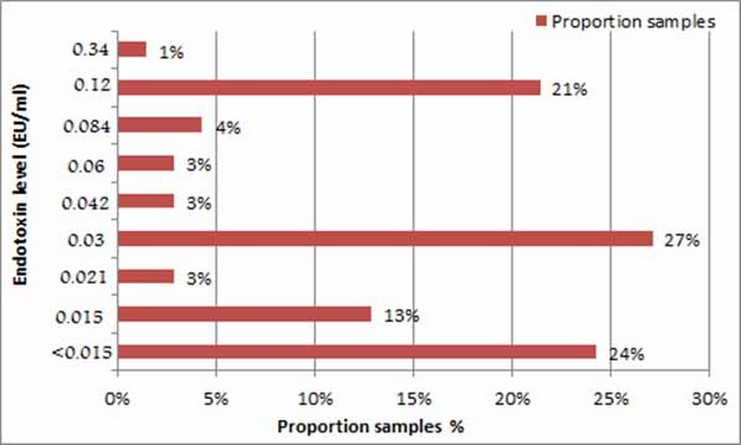

In total, endotoxin assessments complied with the reference quality levels in 47 70 samples during the three-month study period. Endotoxin levels ranged ( from <0.015 - 0.5 EU/ml) in ultrapure dialysis fluid samples, Figure 1.

The endotoxin level of dialysis fluid was below 0.03 EU/ml in 67% of the samples. Only those samples from Iraqi hemodialysis centers met the (ANSI/AAMI/ISO) best practice limits for ultrapure dialysate.

Ultrapure dialysis fluid was unsatisfactory in 23 (33%) Iraqi hemodialysis centers, which might be improved by instituting routine endotoxin investigation.

Figure 1. Endotoxin levels in the treated water in the study samples

DISCUSSION

Our study found that different criteria for evaluating hemodialysis had distinct perceptions and valuations. The microbiologic quality of ultrapure dialysis fluid, defined in terms of the maximum allowed quantities of bacteria and endotoxins, is the primary distinction between ultrapure and standard dialysis fluid (pure).

According to the previous local study, 12 dialysis fluid quality was as high as 50% pure dialysis and 13% ultrapure hemodialysis water; these endotoxin levels did not meet international requirements. 7

Also, another study in Rio de Janeiro found that several clinics (77%), or 17 of 22 medical centers, showed excessive levels of bacterial endotoxin in the LAL test. Microbiological assays frequently fail to identify a bacterial count beyond the standard limit; nevertheless, in the measurement of endotoxins by the LAL test, because it is more sensitive to microbial breakdown products, the presence of the microbe can be experienced even if it cannot be quantified.13

Several published studies have demonstrated that enhancing the microbiological quality of dialysate fluid is connected with various therapeutic advantages. Water and concentrate quality criteria for dialysate production are well established. The European Renal Association Standard requires that the microbiological contamination of provided water adhere to European Pharmacopeia standards.14

For the dialysate to be ultrapure, additional filters must be used. Purified water and ultrapure dialysis fluid production could prevent complications associated with long-term HD therapy and slower loss of remaining kidney function. 15

During and after the implementation of ultrapure water in all dialysis centers. Nephrologists should know that the water treatment system supplier is responsible for ensuring that the water produced meets the maximum permitted endotoxin contamination levels set by the installation standards of ISO/ANSI/AAMI 23500 standards. Beyond this qualification, the nephrologist monitors the system to ensure the treatment devices maintain an acceptable water purity level. They must also transmit the results of bacterial, endotoxin, and chemical levels to the Ministry of Health every month. Corrective steps must be taken if they are not within the permissible range.

Overall, converting a dialysis center to HDF would require significant investment in equipment, training, and infrastructure but may offer benefits for patients in terms of improved dialysis efficiency and removal of more prominent toxins.

CONCLUSION

Providing ultrapure water is essential as a fundamental component of modern HD therapy for minimizing chronic inflammation by depending on tight restrictions enforced by the country's government and ongoing efforts by nephrologists to maintain dialysis water purity at the highest degree. The frequency of endotoxin screening and the policy for contaminated samples varied across centers, which should be addressed in future guidelines. Furthermore, ultrapure water can help preserve the function of the dialysis membrane and prolong the lifespan of dialysis equipment, which can help reduce costs and improve overall efficiency. To summarise, ultra-pure dialysis fluid should be regarded as a fundamental component of modern HD therapy for preventing chronic inflammation and enhancing patient outcomes in high-flux HD. Finally, more than one laboratory for endotoxin measurement is needed for an entire country.

Funding

This research received no specific grant from the public, commercial or nonprofit organizations.

Acknowledgments

The author is grateful for the opportunity to assist the Iraqi Ministry of Health in assessing water quality and enhancing the safety and quality of dialysis in their institutions.

Conflicts of Interest

The author declares no conflict of interest.

REFERENCES

1. Canaud B, Lertdumrongluk P. Ultrapure dialysis fluid: a new standard for contemporary hemodialysis. Nephro-urology monthly. 2012; 4(3):519.

2. Mabel, A, Jihad, M and Walid, A. Ultrapure water in hemodialysis: a step towards a better quality in Lebanon. 2019; 25(2): 134-141.

3. Humudat YR, Al-Naseri SK. Heavy metals in dialysis fluid and blood samples from hemodialysis patients in dialysis centers in Baghdad, Iraq. Journal of Health and Pollution. 2020; 10(27):200901.

4. Mineshima M, Kawanishi H, Ase T, Kawasaki T, Tomo T, Nakamoto H. 2016 update Japanese Society for Dialysis Therapy Standard of fluids for hemodialysis and related therapies. Renal Replacement Therapy. 2018; 4(1):1-4.

5. Ledebo I, Blankestijn PJ. Haemodiafiltration—optimal efficiency and safety. NDT plus. 2010; 3(1):8-16.

6. Penne EL, Visser L, Van Den Dorpel MA, Van Der Weerd NC, Mazairac AH, Van Jaarsveld BC, Koopman MG, Vos P, Feith GW, Hovinga TK, Van Hamersvelt HW. Microbiological quality and quality control of purified water and ultrapure dialysis fluids for online hemodiafiltration in routine clinical practice. Kidney international. 2009; 76(6):665-72.

7. 23500, ISO/ANSI/AAMI. International standard organization/American National Standards Institute/Association for the Advancement of Medical Instrumentation: Water treatment equipment for hemodialysis applications and related therapies. Switzerland. 2019; 1-33.

8. Ledebo I, Nystrand R. Defining the microbiological quality of dialysis fluid. Artificial organs. 1999; 23(1):37-43.

9. Canaud B. The early years of online HDF: How did it all start? How did we get here? Online Hemodiafiltration: The Journey and the Vision. 2011;175:93-109.

10. Humudat YR, Al‐Naseri SK, Imran NJ. Water treatment for hemodialysis in Baghdad Medical City, Iraq. Environmental Quality Management. 2022; 32(2):243-9.

11. Wako-pyrostar. <85> Bacterial endotoxin test. 2012;1-36.

12. Humudat YR and . Kadhim Al-Naseri S. Assessment of endotoxin levels of water in hemodialysis centers in Iraq. Revis Bionatura 2023; 8 (1): 38.

13. Jesus PR, Ferreira JA, Carmo JD, Albertino SR, Vicentini Neto SA, Santos LM, Zamith HP. Monitoring the quality of the water used in mobile dialysis services in intensive care units in the city of Rio de Janeiro. Brazilian Journal of Nephrology. 2021; 44:32-41.

14. Asserraji M, Maoujoud A, Belarbi M, Elfarouki R. Monitoring the microbiological quality of dialysate and treated water. Saudi Journal of Kidney Diseases and Transplantation: an official publication of the Saudi Center for Organ Transplantation, Saudi Arabia. 2014; 25(1):91.

15.Mactier R, Hoenich N, Breen C. Renal association clinical practice guideline on hemodialysis. Nephron. 2011; 118:c241.

Received: 28 May 2023/ Accepted: 15 July 2023 / Published:15 September 2023

Citation: Humudat, Y. Endotoxin quality of ultrapure dialysis fluid for online hemodiafiltration in several hemodialysis centers. Revis Bionatura 2023;8 (3) 30. http://dx.doi.org/10.21931/RB/2023.08.03.30