2023.08.02.83

Files > Volume 8 > Vol 8 No 2 2023

Response of fruits of two pomegranate cultivars to dipping with Chitosan during cold storage

Zeina Sami Rashid and Zena Hazbar Khazaal*

1 College of Agriculture, University of Diyala, Iraq; [email protected].

2 College of Agriculture, University of Diyala, Iraq

Available from: http://dx.doi.org/10.21931/RB/2023.08.02.83

ABSTRACT

The study was carried out in one of the cold stores in Diyala Governorate; the fruits of two cultivars of pomegranate, Salimi and Shami, were collected from the orchards of Diyala Governorate, Khirnabat village, from trees aged 5-6 years. The storage treatments were as follows: two cultivars of pomegranate, Salimi sour and Shami, the fruits were dipped in Chitosan at a concentration of 2% for 5 minutes, in addition to the control treatment (dipping in distilled water only). The fruits were stored at a temperature of 8 ± 1 ° and relative humidity of 85-90% for three months, and measurements were taken at intervals (beginning of storage after 45 days of storage, and after 90 days of storage). The results were analyzed with a factorial experiment with CRD design, and the averages were compared with the LSD test with a probability level of 0.05. The cultivar was significantly superior in the percentage of total soluble solids) 14.10(, anthocyanin pigment)3.005( and total soluble solids / total acidity (TSS/TA)( 19.59) compared with Shami cultivar, while Shami cultivar was significantly superior in total acidity(1.232 ) and vitamin C )26.80(content over Salimi cultivar, the treated fruits with Chitosan at a concentration of 2% gave a clear superiority in the amount of total acidity,( 1.232) the amount of vitamin C(26.80) and the amount of anthocyanin pigment in the fruits compared with the control treatment. At the same time, there was no significant effect of Chitosan on total soluble solids (TSS)( 13.77 ) and TSS/TA(19.26 ). The results also showed that the amount of TSS, the total acidity and the juice content of vitamin C was significantly decreased with the continuation of storage compared with the beginning of storage at the time when the accumulation of anthocyanin(2.209 ) pigment and TSS/TA(19.53) was increased, there was an apparent effect of the interaction between treatments on the storage characteristics of pomegranate fruits.

Keywords: Pomegranate, Chitosan, Fruit and Storage

INTRODUCTION

The pomegranate (Punica granatum L.) is one of the oldest deciduous fruit trees and belongs to the Punicaceae family. 1 Most references indicate that Central Asia, in general, and Persia, in particular, is the original home of the pomegranate, while some researchers believe that China, India and Iraq may be the first places of origin; 2 and it is believed that the most famous producing countries are India, Iran, Turkey, China and the United States of America ;3. The great importance of pomegranate is due to its contains reasonable amounts of vitamins, nutrients, anthocyanins, fats, sugars, organic acids, fiber, protein, pectin and tannin, which differ according to the cultivar.4. Pomegranate has some medical and therapeutic uses resulting from the fact that all parts of the tree contain some compounds of a therapeutic nature, such as anthocyanins and vitamins, especially vitamin C and phenolic substances, which have efficacy as anti- and inhibitory substances for a number of pathogens ;5 as vitamin C is an essential element in increasing immunity in the human body and provides protection from diseases such as cancer and helps heal wounds ;6 Chitosan is a biopolymer with positive charge that is the second largest of biological material in nature after cellulose, Chitosan consists of glucose-amine units linked together by beta-4-1 glycosidic bonds, it has many free hydroxyl and amine groups that enable it to form ionic and hydrogen bonds with other molecules such as fats and proteins ;7It is characterized by its non-toxicity and biodegradability and has no topical or general effects on living tissues ;8 The studies proved that an immersion of fruits with Chitosan leads to reduction of fruit spoilage and prolongs their storage age ;9 It also forms a barrier between the surface of the fruit and O2 when dipping, which reduces the supply of oxygen to the fruit and thus obstruct the breathing, and this makes the fruits keep their nutritional components ;10 Despite the economic, nutritional, medicinal and historical importance of the pomegranate, but the studies about it are limited, especially in the field of postharvest fruit physiology and the importance of pomegranate fruits to the consumer and the lack of studies on storing pomegranate fruits in an optimal way to preserve their essential properties. This study was conducted to determine the best cultivars and the storage treatments that prolong the storage age while preserving their nutritional and marketing value.

MATERIALS AND METHODS

The study was conducted in the laboratories of the College of Agriculture, University of Diyala, on the fruits of two cultivars of pomegranate, Salimi and Shami. The fruits were harvested from one of the orchards in the village of Khirnabat in Diyala Governorate for the season 2019 on October 15, 2019. The healthy fruits free of disease, insect infections, and wounds and scratches were selected and cleaned well by immersing them in sodium hypochlorite solution of 0.05% for 3 minutes; then, the fruits were washed with distilled water and dried. The pre-storage treatments were carried out, which included dipping of fruits with Chitosan solution (German origin) at a concentration of 2% (weight/volume) in addition to the control treatment (dipping with distilled water only) for 5 minutes, the treated fruits were placed in polyethylene plastic bags and stored in the same today in a cold store at a temperature of 8±1°C and relative humidity of 85-90% for three months. Some chemical characteristics of the fruits were taken before storage, then after 45 days and after 90 days. Thus, the treatments and their interactions resulted in 36 experimental units with 3 replicates, then 5 kg of fruits were placed in each replicate; the experiment was completed on 15/1/2020, and the results were analyzed by a factorial experiment of three factors, namely the cultivars (Salimi and Shami), the second factor include dipping in Chitosan with concentrations 2%, the third factor includes storage periods (3 periods). The experiment was carried out with a CRD design, and the averages were compared according to the least significant difference test (LSD) at the 5% probability level 11.

RESULTS

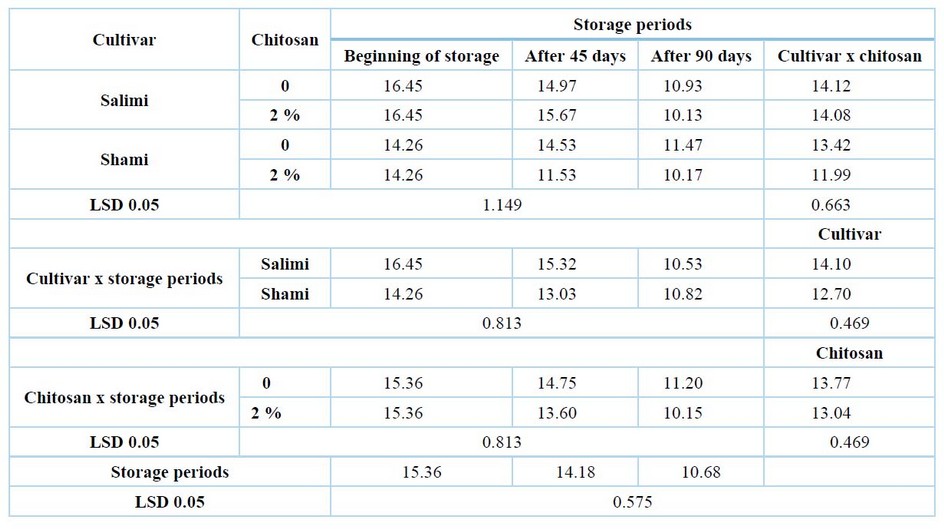

Total soluble solids (TSS %)

The results of Table (1) showed that the treatments had significant and apparent effects on the percentage of total soluble solids; the Salimi cultivar is significantly superior to the Shami cultivar with a share of 14.10%, while the Shami cultivar achieved a rate of 12.70%, the control treatment led to keep a high percentage of TSS in the fruit compared with the treatment of dipping of fruits with Chitosan, which amounted to 13.77%, as for the storage periods, its effect was evident in reducing the percentage of TSS from 15.36% at the beginning of storage to 10.68% at the end of the storage period.

The interaction treatment between Salimi cultivar and the control treatment (without dipping) gave the highest value of 14.12%. In comparison, the Shami cultivar with dipping fruits with Chitosan gave the lowest value, amounting to 11.99%, as for the interaction between the cultivar and the storage periods, the Salimi cultivar at the beginning of storage gave the highest value of 16.45%. In comparison, the same cultivar at the end of storage gave the lowest value of 10.53%; as for the interaction between Chitosan and storage periods, both the control treatment and the dipping of fruits with Chitosan recorded the same high percentage at the beginning of storage, which amounted to 15.36%. In comparison, the lowest percentage of TSS was recorded in the control treatment at the end of the storage period, reaching 10.15%.

As for the triple interaction between the cultivars and the treatments, the highest percentage of TSS was in the two treatments of the interaction between dipping the fruits of the Salimi cultivar with Chitosan 2% and the control treatment (without dipping) at the beginning of storage, where gave same value 16.45%, while the lowest value of TSS was in dipping the fruits of the Salimi cultivar with Chitosan 2% at the end of the storage period, which amounted to 10.13%.

Table 1. Effect of cultivar, dipping with Chitosan and storage periods on the percentage of total soluble solids (TSS)

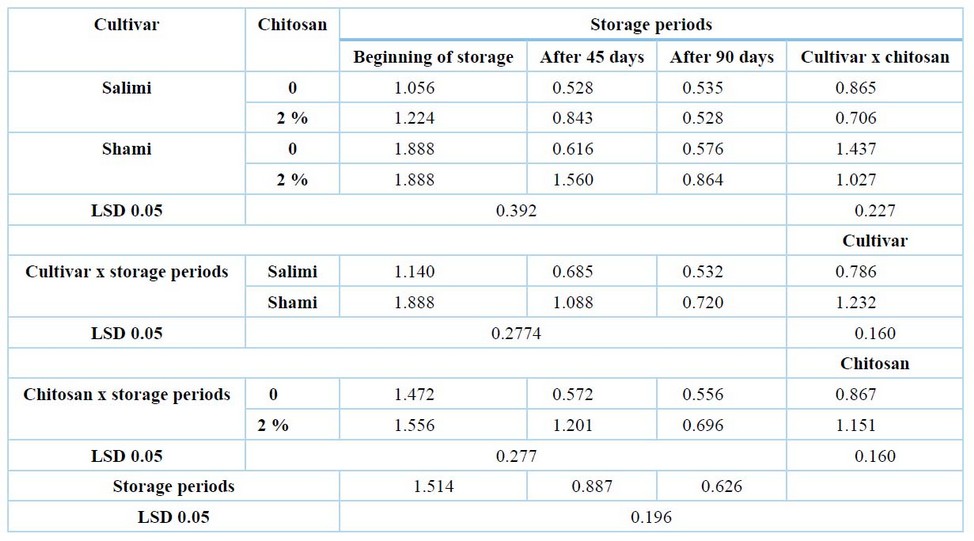

Total acidity (TA %)

The results of Table (2) showed that the Shami cultivar was significantly superior to the Salimi cultivar in the total acidity ratio, which reached 1.232 and 0.786% in both cultivars, respectively; the treatment of dipping the fruits with Chitosan at a concentration of 2% led to an increase in the total acidity percentage, which reached 1.151% compared to the control treatment, which gave the lowest value of 0.867%, as for the storage period, it was noted a decrease in the total acidity percentage with the prolong of the storage period to 0.626%. In comparison, the total acidity percentage at the beginning of storage was 1.514%.

The Shami cultivar with the control treatment recorded the highest percentage of total acidity of 1.437 percent. In contrast, the lowest total acidity was recorded when the Salimi cultivar fruits were dipped in Chitosan at a concentration of 2%, which amounted to 0.706%, as for the interaction between the cultivar and storage periods, the Shami cultivar gave the highest total acidity, which reached 1.888% at the beginning of storage. In contrast, the Salimi cultivar recorded the lowest percentage, which reached 0.532% at the end of storage; as for the interaction between Chitosan and storage periods, the dipping of fruits with Chitosan at the beginning of storage achieved the highest total acidity of 1.556%. In contrast, the control treatment at the end of the storage period recorded the lowest percentage, 0.556%.

The results also show that the triple interaction between the treatments had a significant effect on the total acidity, as the treatments of control and dipping with Chitosan at a concentration of 2% for the Shami cultivar at the beginning of storage gave the highest percentage of total acidity with the same value of 1.888% compared with the lowest percentage in the interaction between the Salimi cultivar and dipping with Chitosan at the end of the storage period 0.528%.

Table 2. Effect of cultivar, dipping with Chitosan and storage periods on the percentage of total acidity

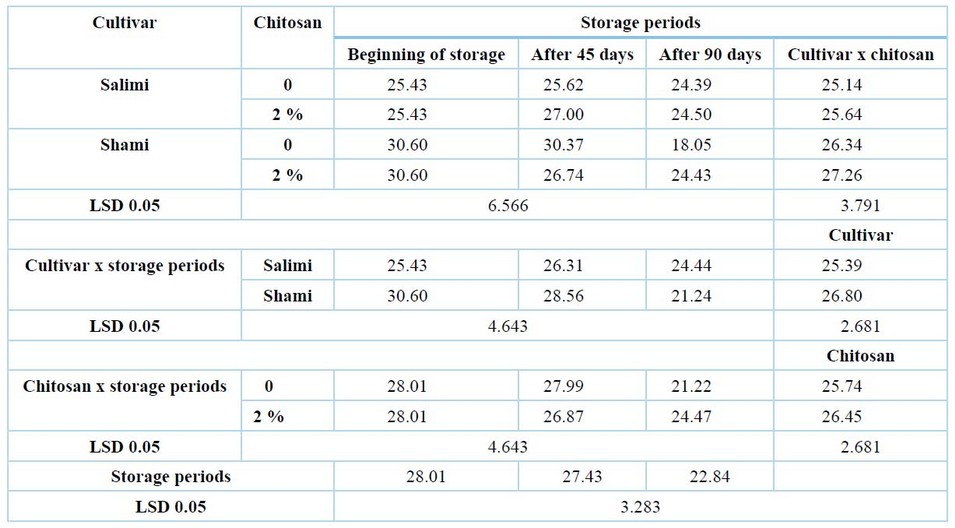

The ascorbic acid content in the juice (mg. 100 ml-1 juice)

Table 3 showed that the Shami cultivar recorded a significant increase in the vitamin C content in the juice, amounting to 26.80 (mg. 100 ml-1 juice). In contrast, the Salimi cultivar recorded the lowest vitamin C content of 25.39 (mg. 100 ml-1 juice).

Dipping pomegranate fruits with Chitosan at a concentration 2% led to a significant increase in the juice content of vitamin C, which was 26.45 (mg. 100 ml-1 juice) compared to the treatment of dipping the fruits with distilled water, which gave 25.74 (mg. 100 ml-1 juice), the storage periods had a significant role in decreasing the juice content of vitamin C, where the highest content was recorded at the beginning of storage 28.01 (mg. 100 ml-1 juice), while the lowest content was recorded at the end of the storage period 22.84%, as for the interaction between treatments of the cultivar and the dipping with Chitosan, the dipping of Shami cultivar with a concentration 2% of Chitosan was recorded the highest content of vitamin C, which amounted to 27.26 (mg. 100 ml-1 juice), while the Salimi cultivar when dipping in distilled water gave the lowest content was 25.14 (mg. 100 ml-1 juice), the Shami cultivar at the beginning of storage showed the highest range of vitamin C of juice was 30.60 (mg. 100 ml-1 juice), while the same cultivar at the end of storage gave the lowest content of vitamin C 21.24 (mg. 100 ml-1 juice). As for the interaction between Chitosan and storage periods, the interaction between dipping and non-dipping of fruits with Chitosan at the beginning of storage reached the same value, which amounted to 28.01 (mg. 100 ml-1 juice), while the lowest value recorded at the control treatment at the end of the storage period was 21.22 (mg. 100 ml-1 juice). It was noted that the triple interaction between the treatments has an apparent effect on the amount of vitamin C, as the control and dipping treatments of fruits with Chitosan at a concentration 2% was superior by giving the highest value of 30.60 mg. 100 ml-1 juice). In contrast, the interaction between Shami cultivar without dipping at the end of the storage period gave the lowest vitamin C content, which amounted to 18.05 mg. for 100 ml-1 juice).

Table 3. Effect of cultivar, dipping with Chitosan and storage periods on ascorbic acid content in the juice (mg. 100 ml-1 juice)

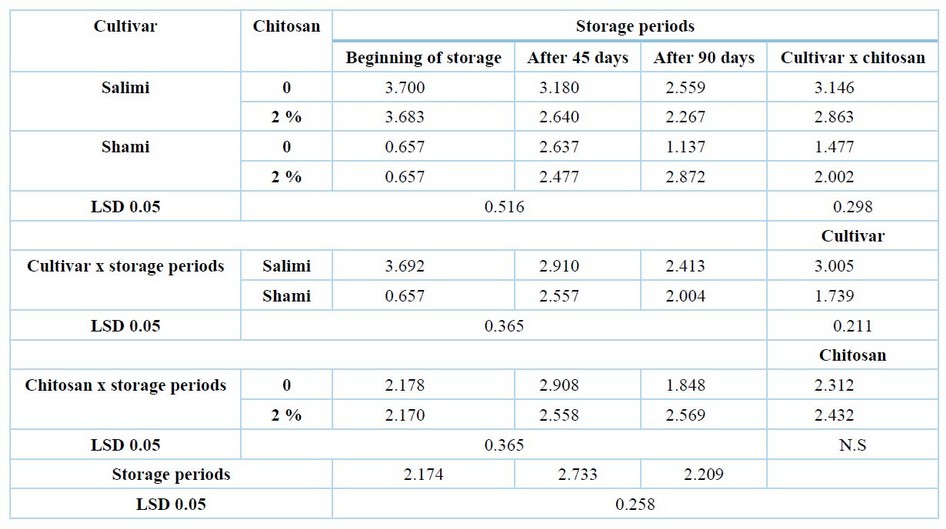

The anthocyanins content in the juice (mg. 100 ml-1 juice)

The results of Table (4) showed that the Salimi cultivar was significantly superior in the juice content of anthocyanin pigment by 3.005 (mg. 100 ml-1 juice) over Shami cultivar which gave the lowest pigment content amounted to 1.739 ( mg. 100 ml-1 juice), as for the treatment with Chitosan, no significant differences were observed between the concentrations of anthocyanin pigment, the storage periods affected the amount of anthocyanin dye content of juice, as the highest value was 2.733 (mg. 100 ml-1 juice) after 45 days from the start of storage compared to the beginning of storage, which was 2.174 (mg. 100 ml-1 juice).

The interaction between the Salimi cultivar and the control treatment recorded the highest dye content of 3.146 (mg. 100 ml-1 juice), while the lowest value recorded by the control treatment for Shami cultivar 1.477 (mg 100 ml-1 juice), The Salimi cultivar achieved the highest content of anthocyanin dye for liquid at the beginning of storage, which reached 3.692 (mg 100 ml-1 juice), concerning the interaction between Chitosan and storage periods, the control treatment after 45 days of storage gave the highest content of 2.908 (mg. 100 ml-1 juice), as for the low dye content for the same treatment at the end of storage, 1.848 (mg. 100 ml-1 juice).

The effect of the triple interaction differed between the treatments, as the control treatment of Salimi cultivar at the beginning of the storage period gave the highest value of 3.700 (mg. 100 ml-1 juice), while the lowest content of anthocyanin dye was 0.657 (mg. 100 ml-1 juice) for the two treatments of dipping and non-dipping with Chitosan together for the Shami cultivar at the beginning of storage.

Table 4. Effect of cultivar, dipping with Chitosan and storage periods on anthocyanins content in the juice (mg. 100 ml-1 juice)

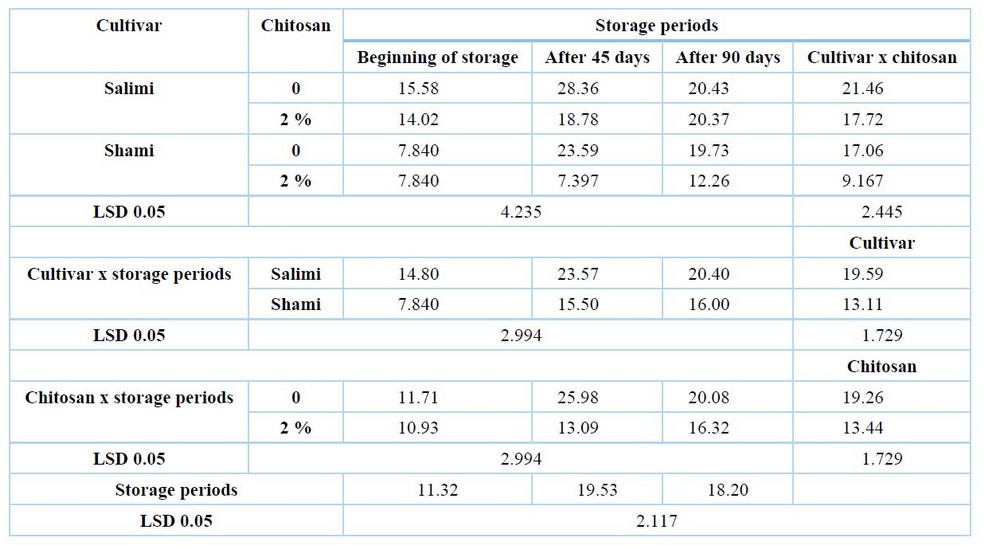

The ratio of TSS/TA

The results of Table (5) showed that Salimi cultivar was significantly superior over Shami cultivar in TSS/TA ratio, where the ratio was 19.59 and 13.1 in both cultivars, respectively, the control treatment (dipping with distilled water only) gave the highest TSS/TA ratio of 19.26 compared to dipping with Chitosan which gave 13.44, the storage periods have different effects on the TSS/TA ratio, where the ratio reached its peak after 45 days of storage and was 19.53, compared to its ratio at the beginning of storage, which was 11.32.

The interaction treatment between the Salimi cultivar and the control treatment gave the highest TSS/TA ratio of 21.46. At the same time, the lowest percentage was recorded when the Shami cultivar was dipped with Chitosan and was 9.167. The highest ratio of TSS/TA for the interaction between the cultivar and the storage periods was recorded in the middle of the storage period for the Salimi cultivar, 23.570. In contrast, the highest percentage was observed when dealing with the interaction of the cultivar Salimi. Still, at the beginning of storage 14.80, the periods of storage and dipping with Chitosan had a significant effect on the TSS/AT ratio, where the highest value was 25.98 when the control treatment after 45 days of storage, while the lowest value was 10.93 when dipping with Chitosan at the beginning of storage. The triple interaction affected the TSS/AT value, the control treatment of Salimi cultivar after 45 days of storage gave the highest value of 28.36, while the lowest value of the TSS/TA was 7.397 when dipping with Chitosan after 45 days of storage for Shami cultivar.

Table 5. Effect of cultivar, dipping with Chitosan and storage periods on TSS/TA ratio

DISCUSSION

The difference in the measured traits for both cultivars may be attributed to genetic differences between the cultivars, as there is a genetic difference between the Salimi cultivar and the Shami cultivar, which is consistent with the findings of 14, 15, 16 and 17. The increase in the chemical content of pomegranate juice (total acidity, ascorbic acid content and anthocyanin content of juice) when dipping the fruits with Chitosan may be attributed to it forms an outer layer around the fruits that prevents the supply of oxygen to the surface of the fruit and reduces the respiration process, thus reduces the consumption of organic acids in the respiration process, which lead to an increase in acidity and vitamin C in fruit juice (Tables 2 and 3); 18. In addition, Chitosan forms a semi-permeable membrane for gases and water around the fruits, thus reducing the transpiration process, raising the water percentage, and lowering the TSS ratio in the fruit juice (Table 1);19. The decrease in the percentage of TSS, total acidity and the content of fruits of vitamin C with the prolonged storage and the increase in the accumulation of anthocyanin pigment are because fruits, after picking, are living organisms and their vital activities continue, the goal of storage is to reduce their vital exercise for the most extended possible period, and the best methods are using cold storage for appropriate periods to protect the fruits and maintain their nutritional and chemical properties, and this is consistent with the findings of differentes authors; 20,21,22.

CONCLUSIONS

The results also showed that the amount of TSS, the total acidity and the juice content of vitamin C was significantly decreased with the continuation of storage compared with the beginning of storage at the time when the accumulation of anthocyanin(2.209 ) pigment and TSS/TA(19.53) was increased, there was an apparent effect of the interaction between treatments on the storage characteristics of pomegranate fruits.

REFERENCES

1. Siddiqui, Rafat A. and Akbar,Mohammed,Pomegranate: Cultivation, Pomological Properties, Processing, Global Market and Health Benefits.(2018). Nova Science Publishers. New York. The USA.

2. Stover, E. and E.W. Mercure. The pomegranate: a new look at the fruit of Paradise. ( 2007 ) HortSci., 42 ( 5 ): 1088-1092.

3. Kahramanoglu, I. Trends in pomegranate sector: production, postharvest handling and marketing. (2019). International Journal of Agriculture Forestry and Life Sciences, 3(2): 239-246.

4. Al-Mayahi, Faleh Hassan Rady. A study of genetic variation and the effect of some physiological treatments on the growth and yield of pomegranate and its content of medically effective compounds. 2018) Doctor's Thesis, College of Agriculture, University of Mosul, Iraq

5. Kandylis, P., and Kokkinomagoulos, E. E. Food applications and potential health benefits of pomegranate and its derivatives. Foods, (2020) 9(2),122:1-21.

6. Joody, A. T..Effect of NPK and Organic Fertilizers on Increasing medicinally active components and limiting heavy metal uptake in pomegranate trees. (2019) Journal of Pharmaceutical Sciences and Research, 11(7): 2770-2773.

7. Dutta, P. K., Dutta, J., and Tripathi, V. S. Chitin and Chitosan: Chemistry, properties and applications. (2004). J. Sci. Ind. Res. India. 63: 20– 31.

8. Ménard, R., S. Alban, P. de Ruffray, F. Jamois, G. Franz, B.Fritig, J. C. Yvin, and S. Kauffmann.. β-1,3 Glucansulfate, but not β-1,3 glucan, induces the salicylic acid signaling pathway in tobacco and Arabidopsis. 2004 Plant Cell.16 3020-3032.

9. Chien PJ, Sheu F, Lin HR. Coating citrus (Murcott tangor) fruit with low molecular weight chitosan increases postharvest quality and shelf life. (2007). Food Chem 100: 1160–1164.

10. JIANG, Y. and LI, Y. Effects of chitosan coating on postharvest life and quality of longan fruit. (2001). Food Chem. 73, 139–143.

11. Al-Khafaji, Makki Alwan. Plant growth regulators and their horticultural applications. (2014) Ministry of Higher Education and Scientific Research, University of Baghdad, Iraq

12. Ranganna,S. Manual of Analysis of fruit and vegetable production tata Mc Graw. 1977.Hill Publishing Company Limited.

13. Ranganna Shandbook of Analysis and Quality Control for Fruits and Vegetable Products, .1986. Tata McGraw-Hill Publishing Company Limited, Second edition.

14. Sharma, K. K., and Dhillon, W. S. Evaluation of evergreen varieties of pomegranate under Punjab conditions. (2002). AgriculturalScience Digest, 22(1): 42-44.

15. Glinicki, R; L.S, paszt; and E.J, Tobjasz. The effect of plant stimulant/fertilizer , resistin, on growth and development of strawberry plants.2010. Journal of Fruit and Ornamental Plant Research. 18(1): 111-124.

16. Taha, M. and G.F Haji. Influence of some biostimulants and seaweed extracts on growth and fruit characteristics of strawberry (Fragaria x ananassa Duch.). (2015). Journal of Zankoy Sulaimani – Part A (JZS-A). Vol.(17), No.(4).

17. El-knew, M. A. Effect of Chitosan, salicylic acid and fulvic acid on vegetative growth, yield and fruit quality of Thompson Seedless grapevines. (2017) Egyptian Journal of Horticulture, 44(1): 45-59.

18. Yonemoto Y, Higuchi H, Kitano Y Effects of storage temperature and wax coating on ethylene production, respiration and shelf-life in cherimoya fruit. (2002). J Japanese Soc for Hort Sci 71: 643–650.

19. Bautista-Banos AN, Hernandez-Lauzardo MG, Velazquez-del Valle M, Hernandez-Lopez E, Ait Barka E, Bosquez M, Wilson CL Chitosan as a potential natural compound to control pre and postharvest diseases of horticultural commodities. (2006). Crop Prot 25: 108–118.

20. Varasteh F. , K. Arzani , M. Barzegar , and Z. Zamani . . Pomegranate (Punica granatum L.) fruit storability improvement using pre-storage chitosan coating technique2017. J. Agr. Sci. Tech. Vol. 19: 389-400.

21. Abd El-Wahab, sahar M., Ali A. F. Abd El-Aziz, Abd ElRahman A. Abd El-Hafeez and Ismail A. I. Emam. Effect of pre-harvest treatments and different cold storage temperatures on fruit quality of "Wonderful" pomegranate. 2017 Middle East J. Agric. Res., 6(4): 1057-1077 .

22. Viswanath M. , B. Srinivasulu, K. Swarajya Lakshmi, K. Gopal and M. Balakrishna. Effect of edible coatings and storage temperatures on maintenance of aril quality and microbial population of pomegranate cv. 2018. Bhagwa Packed in Clamshells .J.Curr.Microbiol.App.Sci . 7(1): 2244-2252.

Received: May 15, 2023/ Accepted: June 10, 2023 / Published: June 15, 2023

Citation: Rashid Z S, Khazaal Z H. Response of fruits of two pomegranate cultivars to dipping with Chitosan during cold storage. Revis Bionatura 2023;8 (2) 83. http://dx.doi.org/10.21931/RB/2023.08.02.83