2023.08.04.80

Files > Volume 8 > Vol 8 no 4 2023

Production and characterization of flavored goat milk gels using zinc and calcium salts Producing functional foods

Qausar ALKaisy 1,2*, Ali Alrikabi1, Jasim Al-Saadi2

1 Department of Food

Science/ College of Agriculture/ University of Basrah/ Iraq; ORCID.

2 Department of Dairy

Science and Technology/ College of Food Science/ AL-Qasim Green University/

Iraq. ORCID 0000-0002-0344-3566.

*Correspondence: [email protected]. edu.iq; Tel.:

009647715967596.

Available from. http://dx.doi.org/10.21931/RB/2023.08.04.80

ABSTRACT

Goat milk gels were prepared using calcium and zinc salts.

The viscosity of gel prepared by adding zinc chloride and flavored with banana

and orange was higher than that of gel prepared using calcium chloride. WHC of

gels prepared using zinc chloride and calcium chloride was high on the first

day and then gradually decreased during storage time at 7 °C. The hardness of

the sweetened, flavored goat milk gel prepared with calcium chloride was lower

than that of the gel prepared with zinc chloride. The Sensory evaluation study

showed that, in general, flavoring gels prepared from goat milk using zinc and

calcium salts had a high degree of acceptability.

Keywords: flavored gel; Zinc chloride; Goat milk; Rheological

properties

INTRODUCTION

Goat's milk is

similar to cow's milk in its elemental composition 1. Goat milk contains 12.2%

total solids, consisting of 3.8% fat, 3.5% protein, 4.1% lactose, and 0.8% ash.

It has more fat, protein, ash, and less lactose than cow's milk 2. Goat milk

contains less total casein but higher non-protein nitrogen than cow's milk 3.

Goat milk has less αs-CN fraction and more κ-CN and β-CN fractions than cow

milk 4.

Milk protein gel formation is an essential and fundamental process in

the dairy industry. This phenomenon occurs when protein-protein interactions

form a three-dimensional network capable of trapping water mole-cules. Several

types of protein gels are produced from milk and its components. The formation

of acid gels is the most important because of its role in the formation of

yogurt and similar products 5. Whey proteins form a gel substance due to

exposure to a temperature higher than 70°C 6. While gels containing both whey proteins

and casein can form during high-temperature storage of UHT milk 7. Heating milk

after adding calcium chloride at concentrations ranging from 7 to 20 mM results

in a gel similar to yogurt's but with a pH close to natural milk's pH of 8.

Despite extensive studies on the effect of added calcium salts on casein

particles, pure caseins, or pure whey protein systems, information about the

effect of heat treatments on the interactions of added calcium with casein and

whey proteins present in milk is limited. The effects of calcium ion activity,

pH, temperature, and ionic strength on the physicochemical and rheological

properties of the gel produced by adding calcium to skim milk were previously

reported 9,10,11. The rheological properties of this type of gel were also

indicated by some researchers 11. This study aimed to prepare flavor gels from

goat milk using calcium and zinc salts and identify their textural and sensory

properties.

MATERIALS AND METHODS

Milk samples

Samples of mixed local goat milk

were collected from several farms in Al-Hilla-Babil - Iraq, and fat was

separated from milk using a milk separator to obtain skim milk.

Preparation of goat milk gels using

calcium and zinc salts

Several preliminary experiments

were established to determine the best conditions to form goat milk protein

gel. Skimmed goat milk samples (100 ml) were heated at 85 °C for 20 minutes,

sugar (7.5%) and flavoring materials (banana, orange, and cocoa flavors used

according to manufacturing companies (made in China) were added to milk

samples, mixed, and cooled to 22 °sC. Calcium chloride and zinc chloride (13.5

mM) were added separately within the normal pH of milk. After that, the milk

samples were heated to 85°C for 20 minutes and left without stirring to produce

a gel. Gels were stored at 7 °C for 28 days.

Gel hardness

Textural properties were evaluated

using a texture analyzer (CT3(4500), Brookfield engineering lab). The hardness

of the samples was measured. The operation conditions were an artificial

plastic cylinder (20 mm in diameter) inserted into each product to a depth

of 20 mm with a 10.0 g trigger and

speed of 1 mm/s 12.

Water Holding Capacity (WHC)

Water-holding capacity (WHC) of

sweetened flavored gel samples was determined as described by 13.

Briefly, 10 g of gel sample was centrifuged at 5000xg for 10 min at 5oC. The

resulting supernatant was carefully weighted to determine the amount of

excluded water, WHC % = [1-(w2 / w1)] ×100

WHC% = [1-(w2 / w1)] ×100

whereas:

W1: Weight of the gel used

W2: Whole weight after

centrifugation

Spontaneous Whey separation (SWS)

Spontaneous whey separation was

determined according to the procedure described by 14. A cup of

flavored gel was removed from the refrigerator and placed at a 45º angle. A

needle connected to a syringe was used to withdraw the liquid whey from the

sample's surface, and the whey's volume was measured. The process lasted for

less than 10s to avoid further leakage of whey from the gel. The spontaneous

whey separation was expressed as the percentage volume of whey over the initial

weight of the gel sample.

Viscosity

The gel was broken by stirring with

a glass rod (10 times clockwise; 10 times anticlockwise). Rotational viscosity

measurements were done utilizing a Brookfield viscometer (model DV- E;

Brookfield Engineering laboratories) utilizing spindle No 3. Separately,

measurement was caused at room temperature at 50 rpm for 1 minute, as described

by 15.

Sensory evaluation

Eight panelists did a sensory

evaluation among the College of Food Science/ Al-Qasim Green University staff

for flavored goat milk gels to estimate the acceptability of gel samples. Gel

specimens were assessed for flavor, body, texture, bitterness, and appearance/color

on a 100-point scale according to the ensuing: flavor 40, body 15, texture 15,

bitterness 20, and appearance/color 10. Mid scores from the eight panelists

were documented16.

RESULTS

Viscosity

of flavored goat milk gels

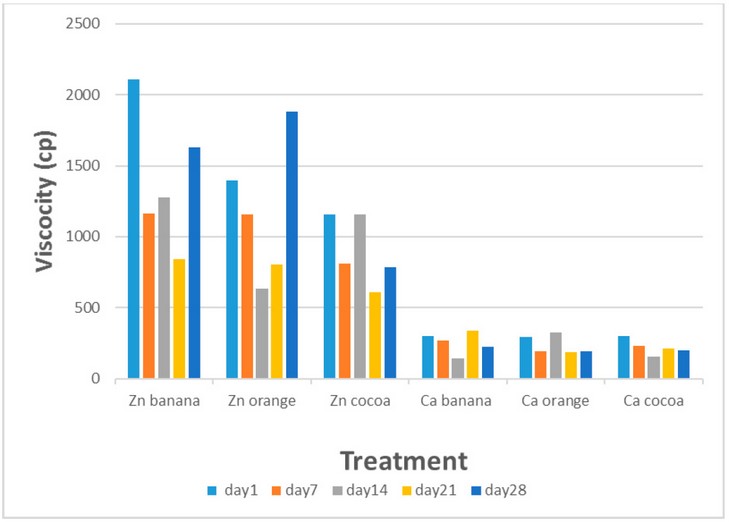

Figure (1) shows the storage

effect on the viscosity of flavored goat milk protein gel. The viscosity of gel

prepared by adding zinc chloride and flavored with banana, orange, and cocoa

were 2110, 1395, and 1154 cp, respectively, while the viscosity for gel

prepared using calcium chloride were 303, 296, and 301 cp, respectively, at day

1 of storage. The viscosity values gradually changed after 28 days of storage

at 7 °C, and they were 1630, 1882, and 786 cp for gel prepared with zinc

chloride and 223, 190, and 200 cp for gel prepared with calcium chloride,

respectively.

Figure 1. Changes in viscosity of

flavored goat milk gel prepared using 13.5 mM of zinc and calcium chloride

during storage at 7 ℃ for 28 days.

Water holding capacity of

flavored goat milk gels

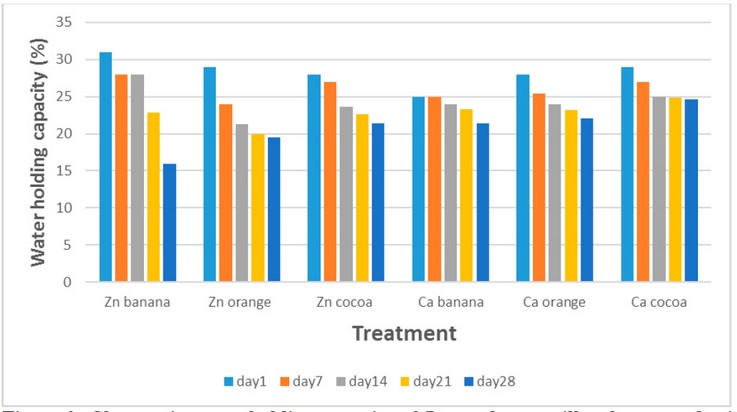

Water

holding capacity is the ability of the gel to hold water within its structure.

Figure (2) shows that the WHC of gels prepared using zinc chloride and calcium

chloride was high on the first day and then gradually decreased during the

progress of storage time at 7 °C. WHC on the first day for goat milk gels

prepared using zinc chloride and flavored with banana, orange, and cocoa

flavors were 31, 29, and 28%, respectively, while WHC for gels prepared with

calcium chloride was 25, 28, and 29 % respectively. These values gradually

decreased to 16, 19.5, 21.4%, 21.4, 22.1, and 24.6%, respectively, after 28

days of storage at 7 °C.

Figure 2. Changes

in water holding capacity of flavored goat milk gel prepared using 13.5 mM of

zinc and calcium chloride during storage at 7 ℃ for 28 days.

Spontaneous whey separation of flavored

goat milk gels.

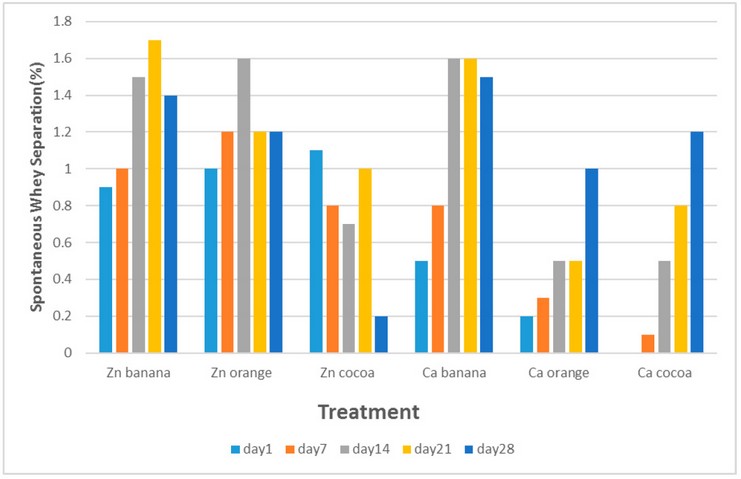

Spontaneous whey separation means liquid exudation at the

top of the gel, which is one of the common defects of yogurt and sweetened gel.

Figure (3) showed that SWS in goat milk gels prepared with zinc chloride and

flavored with banana, orange, and cocoa were 0.9, 1, and 1.1 % in the first-day

storage, while these values in the gel prepared with calcium chloride were 0.5,

0.2, and 0 %, respectively. These values changed after 28 days of storage to

reach 1.4, 1.2, and 0.2 % for the gel prepared with zinc chloride and 1.5, 1,

and 1.2 % for the gel prepared with calcium chloride, respectively.

Figure 3. Changes in spontaneous

whey separation of flavored goat milk gel prepared using 13.5 mM of zinc and

calcium chloride during storage at 7 ℃ for 28 days.

Hardness of flavored goat milk

gels

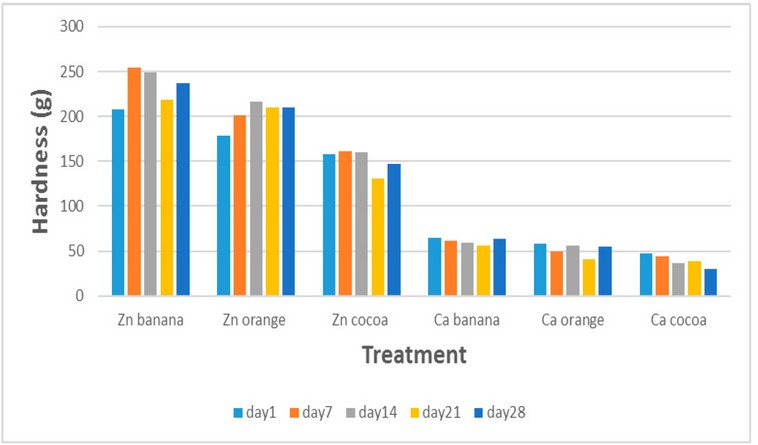

Hardness is the force needed to induce deformation in a gel,

and it is a standard measure to indicate the strength of the gel network being

analyzed. Figure No. (4) showed that the hardness of the sweetened flavored

goat milk gel prepared with calcium chloride was lower than the hardness of the

gel prepared with zinc chloride, where the hardness values for calcium gels

flavored with banana, orange, and cocoa were 64.3, 57.9, 47.6 g, while the

hardness in zinc gels where 207.3, 178.6, 158.4 g, respectively in the 1 day of

storage, and these worth's altered after warehouse for 28 days at 7 ° C to

63.7, 54.4, 30 g for calcium gel and 237.2, 209.4, 147.3 g for zinc gels,

respectively. The difference in the hardness of the gel prepared using

different ions is due to the different ability of these minerals to interfere

with milk proteins and the difference in their binding sites with proteins,

which causes a difference in the three-dimensional structure of the gel network

17.

Figure 4. Changes in flavored

goat milk gel hardness were prepared using 13.5 mM of zinc and calcium chloride

during storage at 7 ℃ for 28 days.

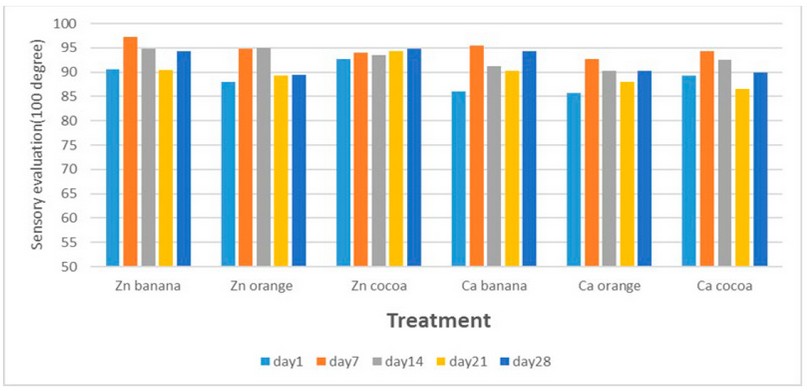

Sensory evaluation of flavored

goat milk gels

In general, flavoring gels prepared from goat milk using

zinc and calcium salts were highly accepted (Figure 5). The total sensory

evaluation scores for the goat milk proteins gel prepared with zinc chloride

and flavored with banana, orange and cocoa on the first day were 90.6, 88.1,

and 92.75, while the scores for gel prepared with calcium chloride were 86,

85.75, 89.25, respectively. These values changed during storage to reach after

28 days to 94.25, 89.5, and 94.75 for gel prepared with zinc chloride and

94.25, 90.25, and 90 for gel prepared with calcium chloride. The gels produced

in this study were distinguished by their delicate texture and acceptable

hardness.

Figure 5.

Sensory evaluation score of flavored goat milk gel crafted utilizing 13.5 mM of

zinc and calcium chloride during storage at 7 ℃ for 28 days.

DISCUSSION

In general, the viscosity values for the sweetened

flavored gel prepared with zinc chloride were higher than the gel prepared with

calcium chloride, and this was due to the extensive loss of water from the gel

prepared by adding zinc chloride. Besides, the change in viscosity values is

due to the change in the properties of the sweetened gel during storage

resulting from increasing interactions between milk proteins and salts. These

results are consistent with what was indicated by 17,18, who

indicated that the hardness of the cow milk gel increased during the storage

period, accompanied by an increase in viscosity. Concerning WHC values

gradually decreased respectively after 28 days of storage at 7°C, and this is

due to the increase in the interaction between salts, caseins, and whey

proteins, which causes caseins to lose their net charges and increase their

hydrophobicity, which leads to a decrease the ability of the gel to hold water.

These results are consistent with the results found by 5,18, and

overall, we notice an increase in SWS during the storage period. It has an

inverse relationship with the water retention capacity of the protein network21,

and this can be due to the increase in the bonds between proteins and minerals

in the gel network, which increases its hydrophobicity and allows the exudation

of whey 18. as well as the difference in the hardness of the gel

prepared using different ions is due to the different ability of these minerals

to interfere with milk proteins, as well as the difference in their binding

sites with proteins, which causes a difference in the three-dimensional

structure of the gel network 18. The differences between the

hardness of milk protein gel produced with different flavors during the storage

period are related to the reactions between these flavors and milk proteins and

ionic salts that affect the interaction between milk proteins, which affects

the hardness6. This may be due to the addition of sugar during the preparation

of the gel, which causes a reduction in the interactions between milk proteins 19.

Panelists did not notice any undesirable taste in the resulting gels, and

although the gels were crafted from skim goat milk, multiple panelists related

them to be creamy. Hence, it may be achievable to utilize this technique to

make quiet-fat dairy outputs with identical textures to those with more

increased fat content.

.

CONCLUSIONS

the

study investigated the effects of different salts on the properties of

sweetened goat milk gels. The results showed that the viscosity of the gels was

higher when zinc chloride was used instead of calcium chloride. This was due to

the more extensive water loss from the gels prepared with zinc chloride. The

WHC of the gels gradually decreased over time, and the SWS increased. This was

due to the increase in the interactions between the salts, caseins, and whey

proteins, which caused the caseins to lose their net charges and increase

hydrophobicity. The panelists did not notice any undesirable taste in the

resulting gels and found them creamy. Therefore, this technique could produce

low-fat dairy products with the same texture as those with higher fat content.

Goat

milk protein gels were constructed from skim milk utilizing heat therapy and

13.5 mM calcium chloride and zinc chloride. Flavoring gels prepared from goat

milk using zinc and calcium salts were highly accepted.

Author

Contributions: Qausar ALKaisy and Jasim Al-Saadi: Methodology,

Resources, Writing-Original Draft. Ali Alrikabi: Conceptualization

Writing-Review & Editing.Jasim Al-Saadi: Writing-Review & Editing. All

authors have reviewed the final manuscript.

Funding: This research received no external funding.

Acknowledgments: We highly thank her (Ashwaq Kadhim-Rahia) for

their valuable help and support through this work. In addition, the financial

support for the in vitro part of this work by Dr. Qaisar Hamad Ghayeb is highly

acknowledged.

Conflicts of

Interest: The authors

declare no conflict of interest.

REFERENCES

1. Rai, D. C., Rathaur, A.,

Yadav, A. K. (2022). Nutritional and nutraceutical properties of goat milk for

human health: A review. Indian Journal of Dairy Science, 75(1). https://epubs.icar.org.in/index.php/IJDS/article/view/121647

2. Park, Y. W. (2010). Goat

milk products: quality, composition, processing, and marketing. Encyclopedia of

animal science. 2nd edition. Taylor and Francis. CRC Press. Boca Raton, FL. e

DOI: 10.1081/E-EAS-120045703

3. Delger, M. (2021). Effect

of seasonality and processing on physicochemical characteristics of goat and

sheep milk: a thesis presented in partial fulfilment of the requirements for

the degree of Master of Food Technology at Massey University, Palmerston North,

New Zealand. Massey University. http://hdl.handle.net/10179/16989

4. Khudai M Y, Abdulateef S

M, Mouhammed T Th, Alamili H S. Use of modern geometric design of fish ponds to

increase welfare and blood parameters. Revis Bionatura 2023;8 (2) 82. http://dx.doi.org/10.21931/RB/2023.08.02.82

5. Lucey,

J., Singh, H. (1998). Formation and physical properties of acid milk gels: a

review. Food research international, 30(7), 529-542. https://doi.org/10.1016/S0963-9969(98)00015-5

6. Zain,

H.; Tatar , A.; Alabi, O. M. .; Samiei Zafarghandi, M. . The Effect Of Using Different Levels Of Vitamin E On The

Antioxidants Status Of Broiler Chickens. JLSAR 2023, 4, 37-44.

7. Torrance L, Cowan GH,

McLean K, MacFarlane S, Al-Abedy AN, Armstrong M, Lim TY, Hein I, Bryan GJ.

Natural resistance to Potato virus Y in Solanum tuberosum Group Phureja.

Theoretical and Applied Genetics. 2020 Mar;133:967-80. https://doi.org/10.1007/s00122-019-03521-y

8. Datta, N., Deeth, H.

(2001). Age gelation of UHT milk—a review. Food and Bioproducts Processing,

79(4), 197-210. https://doi.org/10.1205/096030801753252261

9. Sievanen, K., Huppertz,

T., Kelly, A. L., Fox, P. F. (2008). Influence of added calcium chloride on the

heat stability of unconcentrated and concentrated bovine milk. International

journal of dairy technology, 61(2), 151-155. https://doi.org/10.1111/j.1471-0307.2008.00391.x

10. Koutina, G., Christensen,

M., Bakman, M., Andersen, U., Skibsted, L. H. (2016). Calcium induced skim-milk

gelation during heating as affected by ph. Dairy Science & Technology,

96(1), 79-93.

11. Lin, L., Wong, M., Deeth,

H., Oh, H. (2018). Calcium-induced skim milk gels using different calcium

salts. Food chemistry, 245, 97-103. https://doi.org/10.1016/j.foodchem.2017.10.081

12. Ramasubramanian, L.,

D’Arcy, B. R., Deeth, H. C., Oh, H. E. (2014). The rheological properties of

calcium-induced milk gels. Journal of Food Engineering, 130, 45-51. https://doi.org/10.1016/j.jfoodeng.2014.01.020

13. Ibraheem M W, Muhaimeed A

R, Mohammed Th. T. Leg cuts from Awaasi lambs fed a diet with varying levels of

Rhus coriaria L., Physical dissection and chemical composition. Revis Bionatura

2022;7(4) 4. http://dx.doi.org/10.21931/RB/2022.07.04.4

14. Harte,

F., Luedecke, L., Swanson, B., Barbosa-Canovas, G. (2003). Low-fat set yogurt made from milk subjected to combinations

of high hydrostatic pressure and thermal processing. Journal of Dairy Science,

86(4), 1074-1082. https://doi.org/10.3168/jds.S0022-0302(03)73690-X

15. Amatayakul, T., Sherkat,

F., Shah, N. P. (2006). Syneresis in set yogurt is affected by EPS starter

cultures and levels of solids. International journal of dairy technology,

59(3), 216-221. https://doi.org/10.1111/j.1471-0307.2006.00264.x

16. Donkor, O. N., Nilmini,

S., Stolic, P., Vasiljevic, T., Shah, N. (2007). Survival and activity of

selected probiotic organisms in set-type yoghurt during cold storage.

International Dairy Journal, 17(6), 657-665.

17. Bodyfelt, F. W., Tobias,

J., Trout, G. M. (1988). The sensory evaluation of dairy products. Van Nostrand

Reinhold.

18. N. Khorshed, A., S.

Ahmed, A. Cultivation Of Reishi Mushroom (Ganoderma Lucidum) On Different Local

Substates In Kurdistan Region, Iraq. Anbar Journal Of Agricultural Sciences,

2023; 21(1): 158-173. doi: 10.32649/ajas.2023.179727

19. Ali,

Z. K., Al-Saadi, J. M. (2019). Textural

and sensory properties of milk proteins gels made by ferrous salts. Euphrates

Journal of Agriculture Science, 11(4).

20. Belyakova,

L. E., Antipova, A. S., Semenova, M. G., Dickinson, E., Merino, L. M.,

Tsapkina, E. N. (2003). Effect of

sucrose on molecular and interaction parameters of sodium caseinate in aqueous

solution: relationship to protein gelation. Colloids and Surfaces B:

Biointerfaces, 31(1-4), 31-46. https://doi.org/10.1016/S0927-7765(03)00041-9

21. Niamah,

A. K., Al-Sahlany, S. T. G., Al-Manhel, A. J. (2016). Gum Arabic uses as prebiotic in yogurt production and study

effects on physical, chemical properties and survivability of probiotic

bacteria during cold storage. World applied sciences journal, 34(9),

1190-1196. DOI: 10.5829/idosi.wasj.2016.34.9.184

Received: 26 September 2023 / Accepted: 15 April

2023 / Published: 15 December 2023

Citation: Qausar, A.; Ali A.; Jasim A..Production and characterization

of flavored goat milk gels using zinc and calcium

salts Producing functional foods. Revis Bionatura 2023;8

(4) 80. http://dx.doi.org/10.21931/RB/2023.08.04.80

Publisher's Note: Bionatura stays neutral concerning jurisdictional

claims in published maps and institutional affiliations.

Copyright: © 2023 by the authors. Submitted for possible

open-access publication under the terms and conditions of the Creative Commons

Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).