2023.08.03.85

Files > Volume 8 > Vol 8 No 3 2023

Development of banana (Musa AAA) under different doses of biochar and chemical fertilizers

1 Technical University of Machala, Faculty of Agriculture and Livestock Sciences, Machala, Ecuador. [email protected]

2 Technical University of Machala, Faculty of Agriculture and Livestock Sciences, Machala, Ecuador. [email protected]

3 Yachay Tech, [email protected]

*Correspondence: [email protected]

Available from: http://dx.doi.org/10.21931/RB/2023.08.03.85

ABSTRACT

The main objective of the research was to evaluate the application of different doses of biochar as organic fertilizer to a banana (Musa AAA) crop. The biochar was derived from cocoa pod husks (CPH-B) and banana stalk (BC) and applied to banana plants between 130 and 140 cm tall. The treatments included doses of 32 kg ha-1 (T1) and 48 kg ha-1 (T2) of CPH-B, 32 kg ha-1 (T3) and 48 kg ha-1 (T4) of BC. In all experiments, 100 kg ha-1 potassium nitrate and 100 kg ha-1 phosphorus (P2O5) were applied. Significant differences (p≤0.05) were found in root weight, height and pseudostem circumference at T4. Bunch weights ranged from 16.44 kg (T2) to 21.10 kg (T4). The number of clusters per bunch increased from 6.6 (T1) to 8.5 (T2), with significant differences. Treatments T2 and T4 positively affected plant growth compared to the control plot, suggesting they could be used as an alternative in fertilization programs.

Keywords: banana stalk; cocoa pod husk; nutrients

INTRODUCTION

The production of bananas (Musa AAA) in Ecuador accounts for an annual export income of US$ 3 billion. The harvested area has been estimated at 190,000 ha by 2019, producing approximately 6.5 million tons of fruit1. Ecuadorian banana production generates significant organic waste throughout the harvesting process. For every tone of bananas harvested, approximately 3,000 kg of pseudostem, 480 kg of leaves, 440 kg of peel and 160 kg of stalk can be recovered2. A common practice among banana farmers is to spread organic banana waste on the soil. However, this activity has also been identified as a vector for pests such as mealybugs and thrips3.

On the other hand, banana waste (rotten fruit and stalk) from the harvest represents a significant loss of nutrients to the soil2. This is because nutrients have been extracted from the soil by the crop. Chemical fertilization is therefore used to compensate for the mineral deficiencies in the soil from the last banana production. The use of fertilizer is increasing in banana production because banana crops need a high source of nutrients such as nitrogen (N), phosphorus (P) and potassium (K) to maintain high productivity4. Annual applications of potassium nitrate (960 kg ha-1), potassium chloride (522.8 kg ha-1), urea (393.6 kg ha-1), and ammonium nitrate (376 kg ha-1) are reported in the country to maintain fertile soils in conventional banana crops1,4.

In this context, the continued use of chemical fertilizers on agricultural soils to maintain high productivity has led to soil degradation. Therefore, organic amendments must improve soil parameters such as water retention, biological activity and soil nutrient balance4. In this way, waste biomass from crops is managed sustainably.

Organic banana farmers apply compost and vermicompost from cocoa (Theobroma cacao L.) and banana wastes. However, compost and vermicompost production are time-consuming, preventing their immediate application. An alternative way to reclaim soils and reduce the use of chemical fertilizers is by thermal conversion of organic waste through the pyrolysis process. Pyrolysis is a thermal matter degradation under limited oxygen conditions5. Thus, the biochar application causes physical and chemical soil changes; for instance, biochar contributes to the soil pH equilibrium when the soil is in acidic conditions6,7.

Moreover, the physical and chemical characteristics of the biochar depend on the biomass used as raw material and the pyrolysis conditions such as temperature, heating rate, pressure, and time8. The physical properties of biochar are low bulk density, high porosity, and high specific surface area6. Biochar is also chemically characterized by high cation exchange capacity, alkaline pH, and aromatic and aliphatic functional groups5.

The two most abundant biomasses in Ecuador are the wastes of cocoa and banana harvests. Several studies have characterized the elemental composition of the banana stalk biochar (BC) and the cocoa pod husk biochar (CPH-B). Both biochar have essential carbon levels but different proportions of Mg, Si, P, S, K, and Ca, although biochar is not a significant source of N2,3. Applying biochar does not guarantee enough N and other elements such as Mn, Cu, and Zn5,6,7. For this reason, several researchers recommend mixing the biochar with lime, silicon oxide, or magnesium sulfate to compensate for the nutrients that are not in high proportions and to avoid the concentration of salts (sodium, chlorides, etc.) and to fix elements such as Si and Ca7,9.

Some works show the positive effects of biochar application to the soil; however, there needs to be more data focused on studies of biochar application to the earth during a whole vegetative cycle in banana crops. Therefore, it is hypothesized that using biochar and reduced amounts of chemical fertilizers as organic amendments in soils will result in better plant growth than the exclusive use of the recommended chemical fertilizers. The main aim of the research was to evaluate the application of different doses of biochar as an organic fertilizer for a banana (Musa AAA) crop.

MATERIALS AND METHODS

Study area

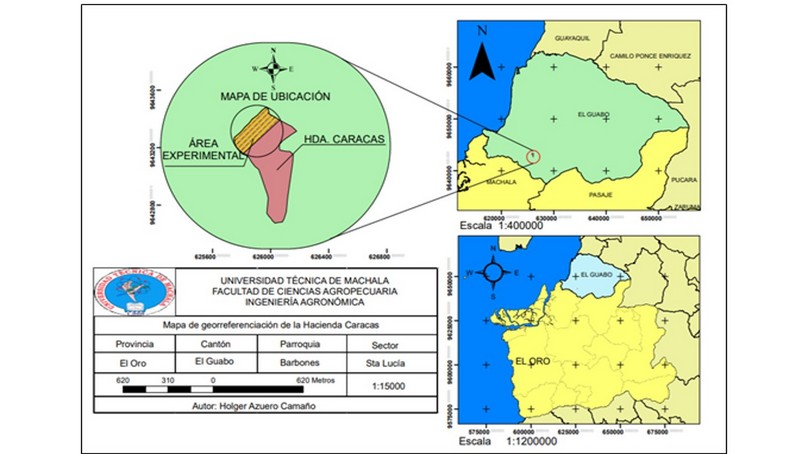

The field experiment was carried out on a banana farm located in Ecuador (3° 14′ 20″ S and 79° 49′ 45″ W) during the season 2019-2020 (Figure 1). Average annual temperatures range from 25 °C to 30 °C, and the yearly precipitation is 750 mm. The giant Cavendish banana clone was selected in this study because it represents more than 50% of the world's banana production, and this banana clone is harvested in Ecuador. The banana plantation was established about 50 years ago with 1837 plants ha-1 (2.52 m between rows and 2.16 m between plants). The characteristics of the banana soil where the experiment was carried out between zero to 15 cm: clay loam, pH 6.5-6.97, Electrical Conductivity (EC) 2.5-4.8 dS m-1, and soil organic matter between 1.93-2.1 %.

Figure 1. Location of the trial

The crop activities that were carried out were those recommended by various authors for the maintenance of the banana farm4. To control Mycosphaerella fijiensis, the main phytosanitary problem of the banana crop, the fungicides mancozeb, chlorothalonil, tridemorph, and propiconazole, mixed with agricultural oil, were applied alternately.

Biochar production

The biochar feedstocks are cocoa pod husk and banana stalks. They were obtained from the farm where the trial was conducted. The biomasses were air-dried for 30 to 45 days. For better uniformity in drying, the banana stalks were cut into 3-5 cm long pieces, while the cocoa pod husks were split in half.

Biochar was produced in a batch thermal reactor with two metal cylinders (Figure 2A). The first cylinder, with a height of 70 cm and a width of 40 cm, functions as a combustion chamber and is closed with a metal lid, with 12 half-inch perforations at the base. This cylinder is located inside a second cylinder, with a height of 120 cm and a width of 50 cm, mounted on a 20 cm high metal base (Figure 2B). Under the metal base is placed the wood to be incinerated, entering the heat through the holes of the combustion chamber.

During the experiment, 4 kg of biomass for each repetition was added inside the thermal chamber (Figure 2C) once the temperature of 350°C was reached8. The temperature was maintained for 3 hours and monitored with a thermal sensor attached to the reactor's inside and a mechanical sight glass placed outside the outer cylinder. The fire was then extinguished and allowed to cool for 12 hours.

The resulting biochar was removed from the combustion chamber, crushed and passed through a 2 mm sieve (Figure 2D). Finally, the biochar samples were stored for 3 months in sealed plastic bags and identified as cocoa pod husk biochar (CPH-B) and banana stalk biochar (BC).

Figure 2. Production of biochar in a thermal reactor

Chemical analysis of biochar

Samples of 10 g of each biochar were taken for pH and EC determination in deionized water at a ratio of 1:2.5 and read in a conductivity meter (Hanna®, model Hi5222-1, Romania). The analyses of each biochar were performed separately and repeated three times for each sample. These chemical determinations were conducted in the Soil Laboratory of the Faculty of Agriculture and Livestock Sciences of the Technical University of Machala.

Experiment design

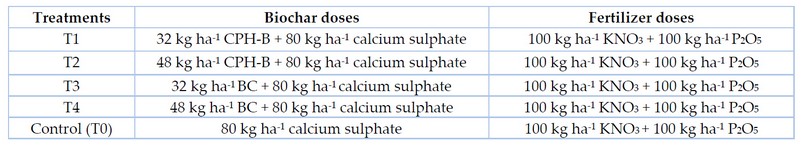

The experiment corresponds to a completely randomized design of four treatments and one control plot. Each treatment was established in 1 hectare. The treatments were applied to all plants within the plots, and 15 plants per treatment were randomly selected. The selected plants were 130 to 150 tall. The doses per treatment applied are detailed in Table 1. In all treatments, doses of 100 kg ha-1 of potassium nitrate (13.5% NO; 3.45% K2O) and 100 kg ha-1 of phosphorus (P2O5) were applied, exempting the control plot where no biochar was implemented. Also, the amendment application of 80 kg ha-1 of calcium sulfate was made in every treatment (including the control plot) by the antecedents of alkaline soils in the area4. In this way, avoid increasing soil alkalinity by the biochar application.

Table 1. Doses of biochar and fertilizers applied per treatment

The distance of the biochar application was 10 cm from the pseudo stem of the banana, spreading it in a crescent shape on the right side of the plant. The biochar applications (for treatments) and fertilizer on the control plot (T0) were replicated twice with an interval of 8 weeks (16 weeks). Harvesting in every selected plant was between 26 to 29 weeks after biochar and fertilizer application.

Measured variables

The pseudostem height and circumference were calculated with a graduated tape from the ground level to the end or beginning of the plant leaf apparition and to the midpoint from the ground to the first leaf branch, respectively. These variables are taken every eight weeks, registering five values per plant.

For dry root weights, five plants were randomly selected per treatment. In front of them were dug 50 cm wide, 60 cm long, and 30 cm deep. The extracted soil roots were cleaned with distilled water, and those greater than 5 mm diameter were separated. They were sieved and registered to obtain an average.

Bunches at harvest of the different treatments were weighed with a scale to corroborate which bunch obtained a higher mass amount. The number of clusters per bunch harvested was counted after each bunch's weight.

At the beginning of the test, the height and circumference values recorded of some plant pseudostem were irregular. It is because the plants do not have synchronized growth, and it depends on many factors; therefore, to have a parameter that indicates how much they grew during the test, the last recorded value was taken and subtracted from the first value. The result of this difference was a value that was treated in an inferential analysis.

Statistical process

The data of the biochar chemical analysis and the soils were subjected to an individual descriptive statistical analysis. A one-way ANOVA and Tukey's Honest Significant Difference (HSD) at 5% significance was used to determine the statistical differences between the four biochar treatments and the control. Also, HDS was applied in the values of difference in pseudostem height and thickness. The obtained values were taken in triplicate and tabulated in a spreadsheet. Then, data was entered into SPSS statistical software version 23.

RESULTS

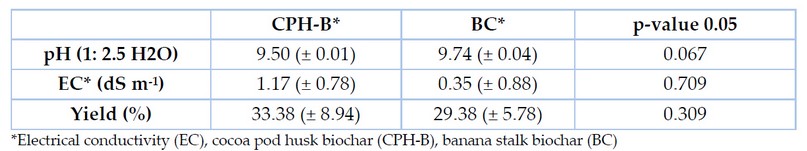

Biochar characterization

Table (2) shows that there is no significant difference in the independent samples T-test (p-value > 0.05). The recorded pH values were 9.50 and 9.74 for CPH-B and BC, respectively; they indicate extreme alkalinity. Besides, the EC was 1.17 dS m-1 and 0.35 dS m-1 for CPH-B and BC values classified as low electrical conductivity. The yield of CPH converted into biochar was 33.38% and 29.38%, respectively. These biochar yield values are related to the percentage of lignocellulosic fiber8. Banana stalks have a higher percentage of cellulose and hemicellulose than cocoa husk, where lignin is the second most abundant fiber6,8.

Table 2. T-test of physic-chemical of CPH-B and BC

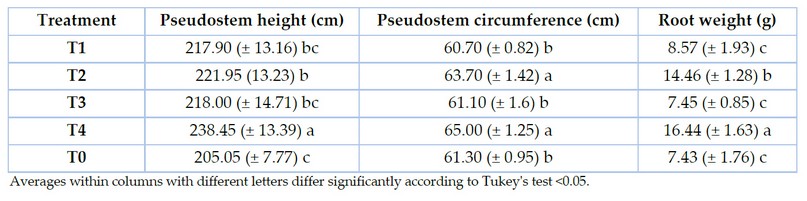

Agronomic Assessment

Tukey's test indicated significant differences (p≤0.05) between the treatments and the control in all variables shown in Table (3). The treatment with the highest pseudostem height eight weeks after application of the first dose was T4 (238.45 cm), followed by T2 (221.95 cm). The T1 and T3 treatments showed values very close to, but higher than, those recorded in the control plot (205.05 cm). Pseudostem height values were higher than those reported in an organically managed banana plantation with doses of 48 kg CPH-B with an average of 217.8 cm10. However, the values obtained are outside the optimal range of pseudostem height (308-368 cm) for plants close to flowering11.

The treatments T4 and T2 had the highest average circumference measurements with 63.70 cm and 65.00 cm, respectively, followed by T0 (61.30 cm), T3 (61.10 cm), and T1 (60.70 cm). All pseudostem circumference values agree with other research results on plants harvested at heights close to 200 cm [11,12]. Likewise, root weights recorded a very noticeable difference between T4 (16.44 g) and T2 (14.46 g) concerning the values of T1 (8.57 g), T3 (7.45 g), and T0 (7.43 g). These values were below average for roots treated with biostimulants in soils of the same textural class but close to previous research where no suppressive treatments were applied to control nematodes 13,14.

Table 3. Effects of different doses for treatment of pseudostem height, pseudostem circumference, and root weights

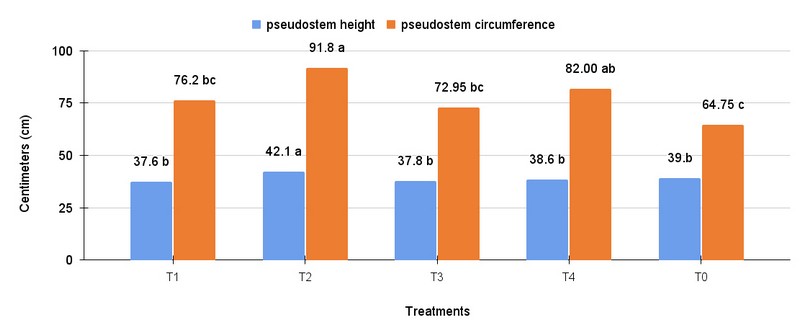

In Figure (2), the difference between the first and last pseudostem height records (Figure 2, bar blue) indicated significant differences (p-value ≤0.05). The highest values were 91.8 cm and 82 cm, corresponding to T2 and T4, respectively, while the lowest value was obtained in the control plot (64.75 cm). In the case of pseudostem circumference (bar orange), Tukey's test (p-value ≤0.05) between the first and last record shows a significant difference between T2 (42.1 cm) and the rest of the treatments and with the control plot.

Figure 3. Comparison of means (Tukey's p-value ≤0.05) between the first and last measurement (bar blue) pseudostem height and pseudostem circumference measurement (bar orange)

Averages within columns with different letters differ significantly according to Tukey's test <0.05.

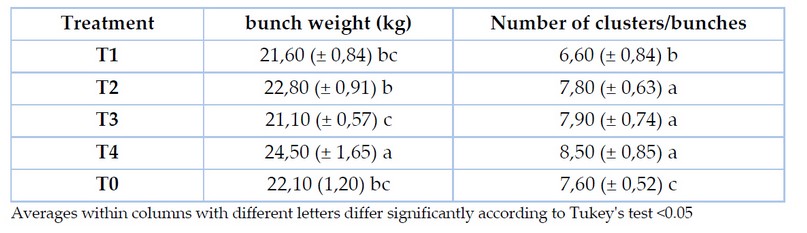

Table (5) shows that Tukey's test indicates significance (p-value ≤0.05) in the weight of bunches harvested. The values from highest to lowest were: 24.50 kg, 22.80 kg, 22.10 kg, 21.60 kg and 21.10 kg, corresponding to T4, T3, T0, T1 and T3, respectively. Also, the number of clusters per bunch harvested indicated significant differences when Tukey's test was performed (p-value ≤0.05). T1 recorded the lowest value (6.6 clusters/bunch) compared to the rest of the treatments. Bunch weight and number of clusters are two variables that correlate positively. In other research10–12,15, the averages vary from 19 to 39 kg bunch weight and 6 to 9 clusters in organically managed plantations and conventional management, respectively.

Table 4. Effects of the different doses per treatment on bunch weight and the number of clusters per bunch harvested

DISCUSSION

Features of biochar

The extreme alkalinity of the two biochars is also reported by previous research on biomasses with high percentages of cellulose (>30 %) and lignin (25 %), which are converted to char at temperatures >300 °C pH16,18. Likewise, the increase in temperature is related to the rise of alkaline cations such as Ca+2, Mg+2, and K+1, which are also related to the change in pH8,17,18. Although cocoa and banana biochar have an extremely alkaline pH, this chemical property can decrease when mixed with calcium sulfate, reducing the possibility of changing the soil pH to alkaline in the short term2.

Also, the composition of cellulose and lignin in the biomass and the temperature directly affected the EC17, which can increase up to 54.2 dSm-1, a record of what is obtained from wood biochar18,19. Several papers report that banana biochar has a high percentage of K, P and Ca5,6. However, the biomass must be incinerated at a temperature higher than 500 °C so that the EC level is also high19. EC level is an essential factor in applying biochar as a soil amendment in agriculture, as it is directly related to the biochar's ability to retain and release nutrients and other ions2,19,20.

Evaluation of plant growth

Pseudostem height and thickness are directly related to N, P, and K nutrients. The treatments with higher doses (T2 and T4) indicate that the dose influences the height but very little on the thickness10. Some researchers suggest that cation exchange in the soil is achieved with biochar produced at higher temperatures9. This leads to excellent stability and porosity, which facilitate cation exchange.

Height and pseudostem girth are two growth variables that highly correlate with plant vigor and yield11,12. High doses of N are required to achieve this optimal development. Nitrogen in several publications indicates ≤ 1% and ≤ 0.5% of N in CPH-B and BC, respectively9,16. When biochar was mixed with chemical fertilizers, values were higher than in other works with biochar6,10. It could be caused by a positive effect associated with several factors, such as the natural soil fertility and the buffer effect of calcium sulfate, which improves the assimilation of other nutrients such as K and P4.

Root weight is related to several factors, such as fertilization, irrigation frequency, high nematode populations, and textural class. Biochar leaches very slowly in clay loam soils and accumulates in the first 5 cm of the topsoil19,20. However, runoff leaches potassium nitrate to a depth of 30 to 45 cm11, where the coarser roots can absorb it. Potassium is only slightly mobile4, so this mixture of biochar and nitrate may have resulted in better K assimilation by the roots in the 5 to 30 cm of the soil14. Therefore, the mixed effect of biochar and fertilizers depends on the texture that would retain the nutrients in the first centimeters and not achieve the whole root zone of the plant.

The values obtained for the number of clusters and bunch weight were like those obtained in other research involving organic bananas but were low compared to banana plantations managed only with chemical fertilizers10,12,15.

A key advantage of using biochar is that it can help reduce fertilizer loss due to evaporation7. This is because biochar enhances cation exchange and increases the availability of nutrients in the top few centimeters of soil. The higher dose used in the biochar + fertilizer trial indicates that it achieved a higher retention of elements that influenced the weight of roots and the development of the pseudostem11,14.

Fertilization is not the only factor affecting clusters and bunch weight in banana production. It is also related to the climatic seasons and the incidence of the pathogen M fijiensis. Seasonal temperatures between 19 and 22°C do not allow adequate physiological bunch development, and the leaf area affected by M fijiensis will cause a decrease in bunch weight 4,23.

CONCLUSIONS

Therefore, the values of the present experiment apply to the conditions under which the plantation was developed; in other conditions, the effects of fertilizers may be very different.

The data obtained are consistent with other research in the chemical characterization of biochar, showing the pH was highly alkaline and low EC. Both characteristics are related to temperature; if it were higher, the pH would remain highly alkaline, the nutrients K, P and Ca would be more available, and salts would increase EC. In this case, the temperature at which the biomasses were incinerated to obtain biochar did not allow for a high EC. To achieve high EC values and higher alkalinity, the biomass must be incinerated at temperatures higher than 450 °C.

The effects of the different biochar and fertilizer treatments on banana pseudostem development, roots, bunch weight and hands were significant compared to the control plot. The highest values correspond to the dose of 48 kg ha-1 in T2 and T4 treatments. However, the treatments did not improve fruit yield.

We recommend this biochar + calcium sulfate and fertilizer for banana cultivation, but experiments should be conducted by obtaining biochar at higher temperatures.

Author Contributions: Conceptualization, Salomon Barrezueta-Unda and Holger Azuero-Camaño; methodology, Salomon Barrezueta-Unda. and Holger Azuero-Camaño; formal analysis, Salomon Barrezueta-Unda; investigation, Holger Azuero-Camaño; visualization, Ivan Goottman; writing—original draft preparation, Ivan Goottman. All authors have read and agreed to the published version of the manuscript.

Funding: This research was funded by the project “Caracterizacion fisicoquimica de la capacidad adsorbente del biochar de cacao y banano sobre el cadmio”, at Technical University of Machala (UTMACH).

Institutional Review Board Statement: "Not applicable."

Informed Consent Statement: "Not applicable."

Conflicts of Interest: "The authors declare no conflict of interest."

REFERENCES

1. Ortiz-Ulloa JA, Abril-González MF, Pelaez-Samaniego MR, Zalamea-Piedra TS. Biomass yield and carbon abatement potential of banana crops (Musa spp.) in Ecuador. Environmental Science and Pollution Research. 2021;28: 18741–18753. https://doi.org/10.1007/s11356-020-09755-4

2. Kabenge I, Omulo G, Banadda N, Seay J, Zziwa A, Kiggundu N. Characterization of Banana Peels Wastes as Potential Slow Pyrolysis Feedstock. Journal Sustainable Development Africa. 2018;11: 14.

3. Omulo G, Banadda N, Kabenge I, Seay J. Optimizing slow pyrolysis of banana peels wastes using response surface methodology. Environmental Engineering Research. 2019;24: 354–361. https://doi.org/10.4491/eer.2018.269

4. Villaseñor D, Prado R, Pereira da Silva G, Carrillo M, Durango W. DRIS norms and limiting nutrients in banana cultivation in the South of Ecuador. Journal of plant nutrition. 2020;43: 2785–2796. https://doi.org/10.1080/01904167.2020.1793183

5. Fetjah D, Ainlhout LFZ, Idardare Z, Ihssane B, Bouqbis L. Effect of Banana-Waste Biochar and Compost Mixtures on Growth Responses and Physiological Traits of Seashore Paspalum Subjected to Six Different Water Conditions. Sustainability. 2022;14: 1541. https://doi.org/10.3390/su14031541

6. Islam M, Halder M, Siddique MAB, Razir SAA, Sikder S, Joardar JC. Banana peel biochar as alternative source of potassium for plant productivity and sustainable agriculture. International Journal of Recycling of Organic Waste in Agriculture. , 2019;8: 407–413. https://doi.org/10.1007/s40093-019-00313-8

7. Domingues RR, Trugilho PF, Silva CA, Melo ICNA de, Melo LCA, Magriotis ZM, et al. Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. Plos One. 2017;12: e0176884. https://doi.org/10.1371/journal.pone.0176884

8. Ghodake GS, Shinde SK, Kadam AA, Saratale RG, Saratale GD, Kumar M, et al. Review on biomass feedstocks, pyrolysis mechanism and physicochemical properties of biochar: State-of-the-art framework to speed up vision of circular bioeconomy. Journal of cleaner production. 2021;297: 126645. https://doi.org/10.1016/j.jclepro.2021.126645

9. Yeboah E, Asamoah G, Kofi B, Abunyewa AA. Effect of Biochar Type and Application Rate on Maize Yield Indices and Water Use Efficiency on an Ultisol in Ghana. Energy Procedia. 2016;93: 14–18. https://doi.org/10.1016/j.egypro.2016.07.143

10. Barrezueta-Unda S, Condoy-Gorotiza A, Sanchez-Pilcorema S. Efecto del biocarbón en el desarrollo de las plantas de banano (Musa AAA) en fincas a partir de un manejo orgánico y convencional. Enfoque UTE. 2022;3. https://doi.org/10.29019/enfoqueute.815

11. Segura RA, Serrano E, Pocasangre L, Acuña O, Bertsch F, Stoorvogel JJ, et al. Chemical and microbiological interactions between soils and roots in commercial banana plantations (Musa AAA, cv. Cavendish). Scientia Horticulturae. 2015;197: 66–71. https://doi.org/10.1016/j.scienta.2015.10.028

12. Vargas A, Guillén C, Arce R. Efecto del manejo del pseudotallo de banano (Musa AAA) a la cosecha sobre la planta sucesora. Agronomia. 2013;21: 19–28.

13. Vidaurre D, Rodríguez A, Uribe L. Edaphic factors and entomopathogenic nematodes in a neotropical banana agroecosystem. Revista de Biología Tropical. 2020;68: 276–288. https://doi.org/10.15517/rbt

14. Torres-Asuaje PE, Cotes-Prado AM, Echeverría-Beirute F, Blanco-Rojas FA, Sandoval-Fernández JA, Segura-Mena RA, et al. Ensilaged biostimulants promoting root health and control of Radopholus similis in banana (Musa AAA) cv. Grande Naine. European journal of plant pathology. 2022. doi:10.1007/s10658-022-02617-4

15. Azuero Gaona BR. Efecto del biocarbón y microorganismos en la producción y estado fitosanitario de banano orgánico en la parroquia La Victoria. 2020 [cited 26 Aug 2021]. Available: http://repositorio.utmachala.edu.ec/handle/48000/15530

16. Karim AA, Kumar M, Singh SK, Panda CR, Mishra BK. Potassium enriched biochar production by thermal plasma processing of banana peduncle for soil application. J Anal Appl Pyrolysis. 2017;123: 165–172. https://doi.org/10.1016/j.jaap.2016.12.009

17. Smebye A, Alling V, Vogt RD, Gadmar TC, Mulder J, Cornelissen G, et al. Biochar amendment to soil changes dissolved organic matter content and composition. Chemosphere. 2016;142: 100–105. https://doi.org/10.1016/j.chemosphere.2015.04.087

18. Chaves BC, Ferreira K, Dias A da Silva V, da Silva T, Silva T, Vander M, Silva D. Impact of Pyrolysis Temperature on the Properties of Eucalyptus Wood-Derived Biochar. Materials. 2022;13: 5081. https://doi.org/10.3390/ma13245841.

19. Suliman W, Harsh J, Abu-Lail N, Fortuna A, Dallmeyer I, Garcia-Perez M. Influence of feedstock source and pyrolysis temperature on biochar bulk and surface properties.” Biomass and Bioenergy. 2016; 84: 37–48. https://doi.org/10.1016/j.biombioe.2015.11.010

20. Munongo ME, Nkeng GE, Njukeng JN. Production and characterization of compost manure and biochar from cocoa pod husks. International Journal of Advanced Scientific Research and Management. 2017;2: 26–31.

21. Araya M, Tapia A, Mata R, Serrano E, Acuña O. Efecto de la aplicación de compost y nematicida sobre la dinámica de las poblaciones de microorganismos, nematodos fitoparásitos del suelo y la salud del sistema radical en el cultivo del banano (Musa aaa) sembrado en domos. Agronomía Costarricense. 2014;38: 93–105.

21. Olivares BO, Araya-Alman M, Acevedo-Opazo C, Rey JC, Cañete-Salinas P, Kurina FG, et al. Relationship Between Soil Properties and Banana Productivity in the Two Main Cultivation Areas in Venezuela. Journal of Soil Science and Plant Nutrition. 2020;20: 2512–2524. https://doi.org/10.1007/s42729-020-00317-8

23. Ramírez-Bolaños S, Pérez-Jiménez J, Díaz S, Robaina L. A potential of banana flower and pseudostem as novel ingredients rich in phenolic compounds. International Journal of Food Science and Technology. 2021;56: 5601–5608. https://doi.org/10.1111/ijfs.15072

Received: 25 June 2023/ Accepted: 26 August 2023 / Published:15 September 2023

Citation: Barrezueta-Unda S A, Azuero-Caamaño H, Goottman Jadan I R. Development of banana (Musa AAA) under different doses of biochar and chemical fertilizers. Revis Bionatura 2023;8 (3) 85. http://dx.doi.org/10.21931/RB/2023.08.03.85